DP-125 GRAY 1.7 FL OZ 3M, DP-125 GRAY 1.7 FL OZ Datasheet - Page 6

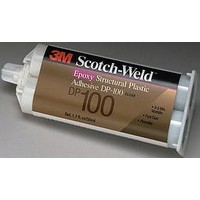

DP-125 GRAY 1.7 FL OZ

Manufacturer Part Number

DP-125 GRAY 1.7 FL OZ

Description

EPOXY 2 PART ADH DUAL CART 1.7FL.OZ

Manufacturer

3M

Series

Scotch Weldr

Datasheet

1.DP-125_GRAY_1.7_FL_OZ.pdf

(7 pages)

Specifications of DP-125 GRAY 1.7 FL OZ

Adhesive Type

Epoxy - 2 Part

Adhesive Applications

Bonding - General Purpose

Color

Gray

Dispensing Method

Dual-Cartridge

Volume

1.7fl.oz. (US)

Pack Quantity

2

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3M

Epoxy Adhesives

DP125 Translucent and Gray

Surface Preparation

Application Equipment

Suggestions

™

Scotch-Weld

For small or intermittent applications the 3M™ EPX™ Applicator System is a

convenient method of application.

For larger applications these products may be applied by use of flow equipment.

Two part meter/mixing/proportioning/dispensing equipment is available for

intermittent or production line use. These systems may be desirable because of their

variable shot size and flow rate characteristics and are adaptable to many applications.

For high strength structural bonds, paint, oxide films, oils, dust, mold release agents

and all other surface contaminants must be completely removed. However, the

amount of surface preparation directly depends on the required bond strength and the

environmental aging resistance desired by user.

The following cleaning methods are suggested for common surfaces:

Steel:

1. Wipe free of dust with oil-free solvent such as acetone, isopropyl or alcohol

2. Sandblast or abrade using clean fine grit abrasives.

3. Wipe again with solvent to remove loose particles.*

4. If a primer is used, it should be applied within 4 hours after surface preparation.

Aluminum:

1. Alkaline Degrease: Oakite 164 solution (9-11 oz./gallon water) at 190°F ± 10°F

2. Acid Etch: Place panels in the following solution for 10 minutes at 150°F ± 5°F .

3. Rinse: Rinse panels in clear running tap water.

4. Dry: Air dry 15 minutes; force dry 10 minutes at 150°F ± 10°F.

5. If primer is to be used, it should be applied within 4 hours after surface preparation.

Note: Read and follow supplier’s environmental, health, and safety documentation for

Plastics/Rubber:

1. Wipe with isopropyl alcohol.*

2. Abrade using fine grit abrasives.

3. Wipe with isopropyl alcohol.*

Glass:

1. Solvent wipe surface using acetone or MEK.*

2. Apply a thin coating (0.0001 in. or less) of primer such as 3M™ Scotch-Weld™

*Note: When using solvents, extinguish all ignition sources, including pilot lights, and

solvents.*

for 10-20 minutes. Rinse immediately in large quantities of cold running water.

Metal Primer EC3901 to the glass surfaces to be bonded and allow the primer to dry

before bonding.

™

these chemicals prior to preparation of this solution.

follow manufacturer’s precautions and directions for use.

Sodium Dichromate

Sulfuric Acid, 66°Be

2024-T3 aluminum (dissolved)

Tap water as needed to balance

- 6 -

4.1 - 4.9 oz./gallon

38.5 - 41.5 oz./gallon

0.2 oz./gallon minimum