MKT1826322014 Vishay, MKT1826322014 Datasheet - Page 10

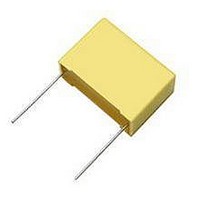

MKT1826322014

Manufacturer Part Number

MKT1826322014

Description

CAPACITOR POLYESTER 0.022UF, 100V, RADIAL

Manufacturer

Vishay

Series

MKT1826r

Datasheet

1.MKT1826247014.pdf

(18 pages)

Specifications of MKT1826322014

Capacitor Application

Safety / Suppression

Capacitor Dielectric Type

Polyester

Capacitance Tolerance

± 5%

Voltage Rating

100VDC

Capacitor Case Style

Radial Leaded

Capacitance

0.022µF

Tolerance

5 %

Termination Style

Radial

Dimensions

2.5 mm W x 7.2 mm L x 6.5 mm H

Lead Spacing

5 mm

Operating Temperature Range

- 55 C to + 125 C

Product

Metallized Polyester Film Capacitors

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

GENERAL

All film capacitors listed in this catalog are manufactured in

plants that have been certified to ISO 9001/ISO 9002

(EN 29001/EN 29002).

ISO 9001 is a comprehensive quality system that comprises

all activities of development, material procurement, production,

quality assurance and customer service. It is based on national

and international standards such as DIN CECC and IEC. All

quality and manufacturing procedures are described in detail

in the Quality Manual of the company.

Modern quality tools such as SPC, FMEA, Zero-Defect quality

programs and Q-Audits serve for the continued improvement

of quality. Constant training programs make sure that all people

involved in the entire process will be kept up to date with the

latest production and quality procedures, thus meeting our

customers requirements.

The following quality terms are alphabetically sorted.

AQL

The Acceptable Quality Level represents the failure share in

the test lot for all sampling instructions of a sampling plan to

which a high acceptance probability is assigned. The AQL is

expressed as the number of faulty components in relation to

100 components.

The sampling inspection is carried out by means of a samp-

ling plan according to DIN ISO 2859 part 1 (identical to

MIL STD 105 or IEC 60410) and is used to evaluate the test

lot.

BATH TUBE CURVE

It represents the characteristic shape of the failure rate over

the operation period. Its course may be divided into three time

phases:

The failure rate at phase II can be assumed to be constant.

BURN-IN

The burn-in or artificial aging of components is a measure

to minimize early failure rates. In the burn-in test the

components are generally subjected to an electrical and

thermal stress.

General Technical Information

Vishay Roederstein

www.vishay.com

12

III. Wear-out phase:

II. Application phase:

I. Early failure phase:

λ

Early Failures

|

Constant Failure Rate

||

Wear Out Failures

For technical questions, contact dc-film@vishay.com

|||

Film Capacitors

t

CPK

Assuming a stable and normally distributed process, the

process capability factor (C

the process versus the tolerance limiting values.

A process is considered to be:

FAILURE

A failure means the unacceptable deviation from at least one

property of a component that was without a defect at the be-

ginning of its application. There are critical failures (e.g. short

or open circuit) and failures caused by exceeding limiting

values.

In case of claims the following information will be required by

the manufacturer:

This information will allow the manufacturer to solve the

problem as quick as possible and to initiate the appropriate

corrective actions.

FAILURE RATE (λ λ λ λ λ )

The failure rate is expressed in “fit” (failures in time) and indi-

cates the number of failures per 10

The calculations of the failure rates are based on

CEI IEC 601709. The fit ratings provided in this catalog refer

to 40°C, 0.5 x U

(The smallest C

x

LSL = Lower specification limit

USL = Upper specification limit

s

Bad if

Acceptable if

Good if

Excellent if

• Kind of defect observed

• Occurrence of the defect (e.g. incoming inspection, burn

• Operating conditions

• Date code (on the component)

• Number of pieces rejected

• Lot size

• Lot number (on the label of the box)

• Return defect samples for failure analysis

1 fit = 1 x 10

N = Number of components tested

n = Number of failures

t

in, reliability test, field)

b

= Test time in hours

= Arithmetic mean value

= Standard deviation

C

PK

λ

ref

= ———— or ————

-9

= ———— [fit]

R

/ h (1 failure per 10

x - LSL

PK

and an upper confidence level of 60%.

-value is valid)

3s

N*

n

C

C

C

C

t

b

PK

PK

PK

PK

< 1.33

≥ 1.33

≥ 1.67

≥ 2.00

PK

) indicates the consistency of

USL - x

3s

9

9

component test hours.

component hours)

Document Number 26033

Revision 01-Dec-03