HMPP-3862-TR1 Avago Technologies US Inc., HMPP-3862-TR1 Datasheet - Page 8

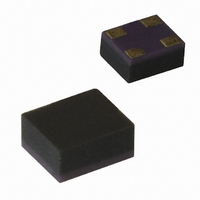

HMPP-3862-TR1

Manufacturer Part Number

HMPP-3862-TR1

Description

DIODE PIN GP 50V 1A MINIPAK

Manufacturer

Avago Technologies US Inc.

Type

Attenuator|Switchr

Datasheet

1.HMPP-3865-BLK.pdf

(10 pages)

Specifications of HMPP-3862-TR1

Diode Type

PIN - 2 Independant

Voltage - Peak Reverse (max)

50V

Current - Max

1A

Capacitance @ Vr, F

0.2pF @ 50V, 1MHz

Resistance @ If, F

22 Ohm @ 1mA, 100MHz

Package / Case

4-MiniPak (1412)

Capacitance Cd Max @ Vr F

0.2pF

Resistance @ If

22ohm

Forward Current If(av)

50mA

No. Of Pins

4

Series Resistance @ If

1.5ohm

Peak Reflow Compatible (260 C)

No

Package

3SOT-23

Configuration

Dual Parallel

Frequency Range

UHF

Maximum Reverse Voltage

50 V

Maximum Diode Capacitance

0.2@50V pF

Capacitance Ct

0.2pF

Breakdown Voltage

50V

Rohs Compliant

Yes

Operating Temperature Classification

Military

Reverse Voltage

50V

Package Type

SOT-23

Mounting

Surface Mount

Operating Temperature (max)

150C

Operating Temperature (min)

-65C

Pin Count

3

Applications Frequency Range

UHF

Forward Current If

1A

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Power Dissipation (max)

-

Lead Free Status / Rohs Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

HMPP-3862-TR1

Manufacturer:

AVAGO

Quantity:

2 100

Part Number:

HMPP-3862-TR1

Manufacturer:

AVAGO/安华高

Quantity:

20 000

Assembly Information

The MiniPak diode is mounted to the PCB or microstrip

board using the pad pattern shown in Figure 17.

Figure 1. PCB Pad Layout, MiniPak (dimensions in mm).

This mounting pad pattern is satisfactory for most ap-

plications. However, there are applications where a high

degree of isolation is required between one diode and the

other is required. For such applications, the mounting pad

pattern of Figure 18 is recommended.

Figure 13. PCB Pad Layout, High Isolation MiniPak (dimensions in mm).

This pattern uses four via holes, connecting the crossed

ground strip pattern to the ground plane of the board.

8

0.40 mm via hole

(4 places)

0.8

0.40

0.4

0.5

2.60

0.4

0.20

0.3

0.5

0.3

2.40

SMT Assembly

Reliable assembly of surface mount components is a

complex process that involves many material, process, and

equipment factors, including: method of heating (e.g., IR

or vapor phase reflow, wave soldering, etc.) circuit board

material, conductor thickness and pattern, type of solder

alloy, and the thermal conductivity and thermal mass of

components. Components with a low mass, such as the

MiniPak package, will reach solder reflow temperatures

faster than those with a greater mass.

After ramping up from room temperature, the circuit board

with components attached to it (held in place with solder

paste) passes through one or more preheat zones. The

preheat zones increase the temperature of the board and

components to prevent thermal shock and begin evapo-

rating solvents from the solder paste. The reflow zone

briefly elevates the temperature sufficiently to produce a

reflow of the solder.

The rates of change of temperature for the ramp-up and

cool-down zones are chosen to be low enough to not

cause deformation of the board or damage to components

due to thermal shock. The maximum temperature in the

reflow zone (T

These parameters are typical for a surface mount assembly

process for Avago diodes. As a general guideline, the circuit

board and components should be exposed only to the

minimum temperatures and times necessary to achieve a

uniform reflow of solder.

MAX

) should not exceed 260°C.