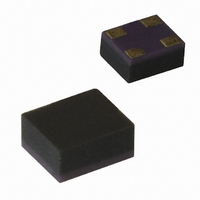

HMPP-3895-TR1 Avago Technologies US Inc., HMPP-3895-TR1 Datasheet - Page 6

HMPP-3895-TR1

Manufacturer Part Number

HMPP-3895-TR1

Description

DIODE PIN SWITCH 100V 1A MINIPAK

Manufacturer

Avago Technologies US Inc.

Datasheet

1.HMPP-3890-TR1.pdf

(13 pages)

Specifications of HMPP-3895-TR1

Package / Case

4-MiniPak (1412)

Diode Type

PIN - 2 Independant

Voltage - Peak Reverse (max)

100V

Current - Max

1A

Capacitance @ Vr, F

0.3pF @ 5V, 1MHz

Resistance @ If, F

2.5 Ohm @ 5mA, 100MHz

Configuration

Parallel

Reverse Voltage

5 V

Forward Continuous Current

1 A

Frequency Range

SHF

Termination Style

SMD/SMT

Carrier Life

0.2 us

Maximum Diode Capacitance

0.3 pF at 5 V

Maximum Operating Temperature

+ 150 C

Maximum Series Resistance @ Maximum If

2.5 Ohms at 5 mA

Maximum Series Resistance @ Minimum If

3.8 Ohms at 1 mA

Minimum Operating Temperature

- 65 C

Mounting Style

SMD/SMT

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Power Dissipation (max)

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

HMPP-3895-TR1

Manufacturer:

AVAGO

Quantity:

415

Part Number:

HMPP-3895-TR1

Manufacturer:

AVAGO/安华高

Quantity:

20 000

Diode Construction

At Avago Technologies, two basic methods of diode fabri-

cation are used. In the case of bulk diodes, a wafer of very

pure (intrinsic) silicon is heavily doped on the top and

bottom faces to form P and N regions. The result is a diode

with a very thick, very pure I region. The epitaxial layer (or

EPI) diode starts as a wafer of heavily doped silicon (the

P or N layer), onto which a thin I layer is grown. After the

epitaxial growth, diffusion is used to add a heavily doped

(N or P) layer on the top of the epi, creating a diode with

a very thin I layer populated by a relatively large number

of imperfections.

These two different methods of design result in two

classes of diode with distinctly different characteristics,

as shown in Table 1.

Table 1. Bulk and EPI Diode Characteristics.

Characteristic

Lifetime

Distortion

Current Required

I Region Thickness

As we shall see in the following paragraphs, the bulk diode

is almost always used for attenuator applications and

sometimes as a switch, while the epi diode (such as the

HMPP-3890) is generally used as a switching element.

Diode Lifetime and Its Implications

The resistance of a PIN diode is controlled by the conductiv-

ity (or resistivity) of the I layer. This conductivity is controlled

by the density of the cloud of carriers (charges) in the I layer

(which is, in turn, controlled by the DC bias). Minority car-

rier lifetime, indicated by the Greek symbol τ, is a measure

of the time it takes for the charge stored in the I layer to

decay, when forward bias is replaced with reverse bias, to

some predetermined value. This lifetime can be short (35

to 200 nsec. for epitaxial diodes) or it can be relatively long

(400 to 3000 nsec. for bulk diodes). Lifetime has a strong

influence over a number of PIN diode parameters, among

which are distortion and basic diode behavior.

To study the effect of lifetime on diode behavior, we first

define a cutoff frequency f

this cutoff frequency can be as high as 30 MHz while for

our longer lifetime diodes f

which are ten times f

act like a current controlled variable resistor. At frequen-

cies which are one tenth (or less) of f

like an ordinary PN junction diode. Finally, at 0.1f

10f

6

C

, the behavior of the diode is very complex. Suffice it

C

(or more), a PIN diode does indeed

EPI Diode

Short

High

Low

Very Thin

C

= 1/τ. For short lifetime diodes,

C

≅ 400 KHz. At frequencies

C

, a PIN diode acts

Bulk Diode

Long

Low

High

Thick

C

≤ f ≤

to mention that in this frequency range, the diode can

exhibit very strong capacitive or inductive reactance — it

will not behave at all like a resistor. However, at zero bias

or under heavy forward bias, all PIN diodes demonstrate

very high or very low impedance (respectively) no matter

what their lifetime is.

Diode Resistance vs. Forward Bias

If we look at the typical curves for resistance vs. forward

current for bulk and epi diodes (see Figure 15), we see

that they are very different. Of course, these curves apply

only at frequencies > 10 f

of resistance vs. bias current for the bulk diode is much

higher than that for the epi (switching) diode. Thus, for a

given current and junction capacitance, the epi diode will

always have a lower resistance than the bulk diode. The

thin epi diode, with its physically small I region, can easily

be saturated (taken to the point of minimum resistance)

with very little current compared to the much larger bulk

diode. While an epi diode is well saturated at currents

around 10 mA, the bulk diode may require upwards of

100 mA or more. Moreover, epi diodes can achieve rea-

sonable values of resistance at currents of 1 mA or less,

making them ideal for battery operated applications.

Having compared the two basic types of PIN diode, we

will now focus on the HMPP-3890 epi diode.

Given a thin epitaxial I region, the diode designer can

trade off the device’s total resistance (R

capacitance (C

and I region. The HMPP-3890 was designed with the 930

MHz cellular and RFID, the 1.8 GHz PCS and 2.45 GHz RFID

markets in mind. Combining the low resistance shown

in Figure 15 with a typical total capacitance of 0.27 pF, it

forms the basis for high performance, low cost switching

networks.

Figure 15. Resistance vs, Forward Bias.

Figure 10. Resistance vs. Forward Bias.

1000

100

10

0.01

1

j

) by varying the diameter of the contact

Epi PIN Diode

HMPP-389x

0.1

BIAS CURRENT (mA)

HSMP-3880 Bulk PIN Diode

C

. One can see that the curve

1

10

S

+ R

j

) and junction

100