171662-1 TE Connectivity, 171662-1 Datasheet - Page 21

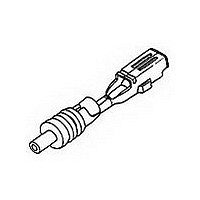

171662-1

Manufacturer Part Number

171662-1

Description

E-J MK-2 070 REC CONT

Manufacturer

TE Connectivity

Type

Contactr

Series

070r

Datasheet

1.171662-1.pdf

(80 pages)

Specifications of 171662-1

Gender

RCP

Body Orientation

Straight

Housing Material

Not Required

Number Of Contacts

1POS

Number Of Ports

1Port

Number Of Terminals

1

Pitch (mm)

Not Requiredmm

Contact Material

Brass

Operating Temp Range

-30C to 105C

Mounting Style

Cable

Termination Method

Crimp

Contact Plating

Pre-Tin

Product Height (mm)

3.6mm

Product Depth (mm)

5.4mm

Product Length (mm)

16.5mm

Product Line

Econoseal J

Product Type

Contact

Wire/cable Type

Discrete Wire

Cable Type

Thin Wall

Termination Method To Wire/cable

Crimp

Wire/cable Size (awg)

16 – 20

Wire/cable Size (mm²)

0.5 – 1.25

Wire Type

Stranded

Contact Type

Socket

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Pre-Tin

Contact Plating, Mating Area, Thickness (µm [?in])

0.76 [29.92]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

2.00 – 2.60 [0.079 – 0.102]

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Reel

Packaging Quantity

6000

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

171662-1

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

171662-1

Manufacturer:

TE/TYCO

Quantity:

6 600

A

AMP Sealed Connectors

Contacts

Wire Seals

Connector Housings

0.8 mm [.031 in.] wide tab

contacts.

Tab contacts are made from

pre-tin plated brass.

Receptacle contacts are

made from pre-tin plated

phosphor bronze.

Lanceless contact design to

eliminate tangling.

Wire range 0.3 - 0.5 mm

[#22 - #20 AWG].

A poke through (matte) wire

seal design

For insulation diameters

1.4 - 1.7 mm [.055 - .067 in.].

Seal material is NBR.

Connector housings

produced from green, glass

filled PBT.

Currently available only as

a seven position connector.

Cavity plugs are available

to seal unused connector

cavities.

Easy inspection for

improperly inserted

contacts

AMP Technical Support Center/AMP FAX Service

1-800-522-6752 717-986-7777

2

AMP Sealed Connectors

Mini MULTILOCK Wire to Wire Connector

AMP Mini MULTILOCK is

among the worlds smallest

waterproof connector

systems. Originally

designed for use with the

rotary driving circuits of

automobile door mirror

units, they are suitable for

most applications requiring

small, water resistant

connectors.

Assembly is simplified with

the use of snap in crimp

contacts and poke through

wire seals. All seals are pre-

loaded into the connector

housings.

The connector housings

are designed to prevent

incorrect contact insertion.

When contacts are properly

inserted into the connector

housing they produce an

audible click to indicate the

contact has been oriented

correctly and completely

inserted.

Cavity plugs are available

to seal unused connector

cavities for applications in

which not all seven

connector circuits are

required.

All seals and sealing

surfaces are located inside

of the connector housing to

help eliminate possible

damage during handling.

Dimensions are in

millimeters over [inches]

www.amp.com

Product Performance

Temperature Rating

-40° to 105° C. (including temperature

rise due to current load).

Termination Resistance

10 m (Initial)

20 m (Final)

Dielectric Withstanding Voltage

1.0 kVAC for one minute.

Current Guidelines

See page 11 of product specification

108-5426 for information.

Product Documentation

Product Specification

108-5426

Application Specification

114-5193

Customer Manual

412-5653

Specifications

subject to change.

Revised 01-00

Catalog

65481

21