LMD18245T/NOPB National Semiconductor, LMD18245T/NOPB Datasheet - Page 17

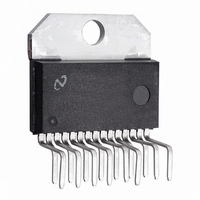

LMD18245T/NOPB

Manufacturer Part Number

LMD18245T/NOPB

Description

IC H BRIDGE 3A 55V TO-220

Manufacturer

National Semiconductor

Datasheet

1.LMD18245TNOPB.pdf

(21 pages)

Specifications of LMD18245T/NOPB

Applications

DC Motor Driver, Stepper Motor Driver, H Bridge

Number Of Outputs

1

Current - Output

3A

Voltage - Supply

12 V ~ 55 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Through Hole

Package / Case

TO-220-15 (Bent and Staggered Leads)

Operating Temperature Classification

Automotive

Package Type

TO-220

Operating Supply Voltage (min)

12V

Operating Supply Voltage (max)

55V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Voltage - Load

-

Lead Free Status / Rohs Status

Compliant

Other names

*LMD18245T

*LMD18245T/NOPB

LMD18245T

*LMD18245T/NOPB

LMD18245T

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LMD18245T/NOPB

Manufacturer:

ST

Quantity:

14 300

Part Number:

LMD18245T/NOPB

Manufacturer:

NS/国半

Quantity:

20 000

The Typical Application

HALF STEP DRIVE WITH TORQUE COMPENSATION

To make the motor take half steps, the windings can also be

energized with sinusoidal currents (Figure 12). Controlling

the winding currents in the fashion shown doubles the step

resolution without the significant torque ripple of the prior

drive technique. The motor takes one half step each time the

level of either winding current changes. Half step drive with

torque compensation is microstepping drive. Along with the

obvious advantage of increased step resolution, micro-

stepping reduces both full step oscillations and resonances

that occur as the motor and load combination is driven at its

Top Trace: Phase A Winding Current at 1A/div

Bottom Trace: Phase B Winding Current at 1A/div

Horizontal: 2 ms/div

*500 steps/second

BRAKE A = BRAKE B = 0

FIGURE 12. Winding Currents and Digital Control Signals for Half Step Drive with Torque Compensation

90˚ ELECTRICAL/FULL STEP ÷ 2 MICROSTEPS/FULL STEP = 45˚ ELECTRICAL/MICROSTEP

(Continued)

17

natural resonant frequency or subharmonics thereof. Both of

these advantages are obtained by replacing full steps with

bursts of microsteps. When compared to full step drive, the

motor runs smoother and quieter.

Figure 13 shows the lookup table for this application of the

typical application circuit. Dividing 90˚electrical per full step

by two microsteps per full step yields 45˚ electrical per

microstep.

ments of 45˚. Each full 360˚ cycle comprises eight half steps.

Rounding |cos | to four bits gives D A, the decimal equiva-

lent of the binary number applied at M4 A through M1 A.

DIRECTION A controls the polarity of the current in winding

A. Figure 12 shows the sinusoidal winding currents.

, therefore, increases from 0 to 315˚ in incre-

01187824

www.national.com

01187844