853400-8 Tyco Electronics, 853400-8 Datasheet - Page 4

853400-8

Manufacturer Part Number

853400-8

Description

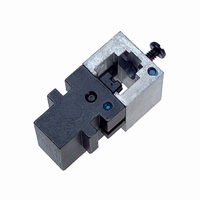

DIE, 6 POS MOD PLUG IS9611

Manufacturer

Tyco Electronics

Type

Dier

Datasheets

1.1673606-1.pdf

(8 pages)

2.2-231652-0.pdf

(7 pages)

3.853400-1.pdf

(2 pages)

4.853400-1.pdf

(6 pages)

Specifications of 853400-8

Connector Type

Modular Connector, 6 pos

Crimp Handle

A9931-ND (2-231652-0)

Rohs Compliant

NA

Product

Punches & Dies

Lead Free Status / RoHS Status

Not applicable / Not applicable

Crimp Or Cable Size

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

231651-2

313879-2

853400-2

A9905

313879-2

853400-2

A9905

4 of 6

Step 2

Step 1

Step 3

4. After releasing the terminated plug, inspect for

proper crimp height using a dial indicator or digital

indicator with needle--point probes, or Crimp Height

Gage 904170--1 according to 408--4389.

5. Figure 5 shows a cross--section of a typical

terminated plug—proper crimp height dimension

and required location of the conductors. A visual

inspection through the plastic housing of the plug

should reveal whether the conductors are within

acceptable range.

NOTE

i

Refer to 114- - 6016 for specific information

concerning inspection requirements.

Die

Cavity

Terminating Modular Plug

Plug Locking

Tab

Figure 4

Cable Bottomed in Plug

Plug Oriented as

Shown on Side

of Tool Head

Locking

Tab (Ref)

Tyco Electronics Corporation

5. TOOL ADJUSTMENTS

5.1. Adjusting the Cable Stripper

If cable jacket is cut too shallow and does not strip

properly from the conductor bundle, or if it is cut too

deeply and conductor insulation is also cut, then refer

to Figure 6 and adjust the cable stripper on the hand

tool as follows:

5.2. Replacing Cable Stripper Blades

If the cable stripper blades are worn or damaged,

refer to Figure 7 and replace the fixed blade assembly

and movable blade assembly as follows:

CAUTION

NOTE

1. Close tool handles until the dies bottom, but DO

NOT release the handles.

2. Loosen the two screws that hold the movable

blade assembly.

3. Insert the blade set--up gage (part of the blade

replacement kit included with the tool) or a

1.02 mm [.040 in.] shim between the stationary

and movable blades. Slide the movable blade

against the gage (or shim) and tighten the screws.

NOTE

1. Remove the four screws holding both blades in

place. Remove fixed blade assembly and movable

blade assembly from tool.

2. Position new blades onto tool with beveled

edges facing inward.

i

!

i

6.02+0.13 [.237+.005]

Crimp Height

Crimped Modular Plug Inspection

The die set must be in the tool when adjusting

the flat cable stripper.

Do NOT cycle hand tool without a die in place.

Damage to the stripping blades may occur.

The recommended shim thickness does not

account for larger than normal conductor

insulation. Adjust the blade gap according to your

specific needs.

0.64 [.025] (Max)

Conductor Location

Figure 5

Cross- - Section of

Crimped Modular Plug

Rev D