1981568-1 TE Connectivity, 1981568-1 Datasheet - Page 50

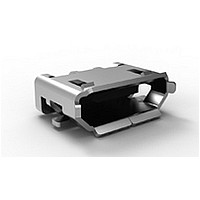

1981568-1

Manufacturer Part Number

1981568-1

Description

REC TYPE B ASSY (AU) MICRO USB

Manufacturer

TE Connectivity

Series

DisplayPort Receptacles and Cable Assembliesr

Datasheet

1.1981568-1.pdf

(116 pages)

Specifications of 1981568-1

Number Of Contacts

5POS

Body Orientation

Right Angle

Contact Material

Copper Alloy

Operating Temp Range

-55C to 85C

Current Rating (max)

1/ContactA

Voltage Rating Max

30VAC

Product Height (mm)

3mm

Number Of Ports

1Port

Gender

RCP

Mounting Style

Surface Mount

Contact Plating

Gold Over Nickel

Housing Material

Thermoplastic

Product

Micro USB Type B Connectors

Standard

USB

Pitch

0.65 mm

Current Rating

1 A

Termination Style

Solder Pad

Connector Type

Micro USB Type B Receptacle

Color

Black

Features

Without Locking Feature

Flammability Rating

UL 94 V-0

Insulation Resistance

100 MOhms

Mounting Angle

Right

Number Of Positions / Contacts

5

Operating Temperature Range

0 C to + 50 C

Voltage Rating

30 VAC

Size

Micro

Orientation

Right Angle

Mount Location

Top

Termination Method

Surface Mount

Locking Feature

Without

Led

Without

Panel Ground

Without

Pcb Mount Retention Type

SMT Hold Down

Shell Plating

Reflowed Tin over Nickel

Assembly Process Feature

Without Pick and Place Cover

Locating Post(s)

Without

Number Of Positions

5

Contact Termination Type

Surface Mount

Contact Plating, Mating Area, Material

Gold

Contact Plating, Mating Area, Thickness (µm [?in])

0.762 [30]

Housing Color

Black

Industry Standard

USB 2.0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Reflow solder capable to 245°C

Rohs/elv Compliance History

Always was RoHS compliant

Usb-if Test Id Number (tid)

60001336

Applies To

Printed Circuit Board

Pcb Thickness, Recommended (mm [in])

1.00 [0.039]

Packaging Method

Tape & Reel

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

1981568-1

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

1981568-1

Manufacturer:

TE

Quantity:

20 000

Product Facts

■

■

■

■

■

■

■

■

■

■

■

■

■

Modifications & Options

The flexible elastomeric

manufacturing process

allows a fast, easy modifi-

cation of the products to

suit the individual needs

of the application. Typically

with an elastomer-only

solution there is no tooling.

There are requirements

for minimum production

volume.

48

Single piece compression

connector

Contact pitch as lows as

0.8 mm

No. of rows of contacts:

1 through 5 (two rows shown

to the right)

No. of Contacts: 1–200

Board Separation:

0.5–8.0 mm

Shielding Capability

Performs in high-speed

applications (3 GHz)

Low resistance

Current Capability:

1 Amp typical with higher

capability possible with

modification

Easily modified standard

designs

Facilitates automatic

assembly, rework, and field

upgrades

Compatible with tin and

flash gold contact metallurgy

Rugged and reliable

Products for Mobile Equipment

Connectors

STAX™ LD Elastomeric Connectors

STAX™ LD Elastomeric Connectors

Surface-to-Surface Compression Connection for Board Stacking Applications

Dual-Row STAX Connector connects two rows of contact pads. Retention slot is provided in PCB separator.

Elastomeric connectors are

viable in most applications

where traditional board-board

connectors are used. The

applications may include high

speed, power, digital, ground-

ing/shielded interconnect.

The elastomer is a single piece

compression technology. The

silicone within the connector

provides the normal force

(spring). The conductive layers

(blend of silicone and silver

particles) make redundant

electrical contact to the pads

on the board.

The STAX LD technology is

based upon 30 years of

experience in manufacturing

and in the hundreds of millions

of connectors used in trouble-

free applications. This is a low

durometer and low contact

resistance product.

All specifications subject to change. Consult Tyco Electronics for latest specifications.

Tyco Electronics maintains

complete control over the

quality and performance of the

product. The STAX product

line is manufactured from basic

raw materials (silver or gold,

and silicone) using a proprie-

tary manufacturing process.

The result is a connector

technology that allows the

freedom of design without the

traditional limitations of stand-

ard product availability. There

is no need to compromise

the end product at the design

stage.

Mechanically, the elastomeric

capabilities are flexible. The

technology can meet PCB

area requirements in appli-

cations of board separations

under 8.0 mm. Electrically,

resistance and current ratings

are competitive with most

alternative technologies.

How STAX Elastomeric

Connectors Work

STAX elastomers are zero

insertion force connectors

that do not require soldering.

They provide a compliant

surface-to-surface com-

pression connection when

deflected between opposing

mirror-image pad patterns.

Catalog 1654270-2

Revised 8-2007