1981568-1 TE Connectivity, 1981568-1 Datasheet - Page 60

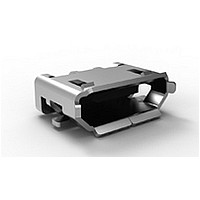

1981568-1

Manufacturer Part Number

1981568-1

Description

REC TYPE B ASSY (AU) MICRO USB

Manufacturer

TE Connectivity

Series

DisplayPort Receptacles and Cable Assembliesr

Datasheet

1.1981568-1.pdf

(116 pages)

Specifications of 1981568-1

Number Of Contacts

5POS

Body Orientation

Right Angle

Contact Material

Copper Alloy

Operating Temp Range

-55C to 85C

Current Rating (max)

1/ContactA

Voltage Rating Max

30VAC

Product Height (mm)

3mm

Number Of Ports

1Port

Gender

RCP

Mounting Style

Surface Mount

Contact Plating

Gold Over Nickel

Housing Material

Thermoplastic

Product

Micro USB Type B Connectors

Standard

USB

Pitch

0.65 mm

Current Rating

1 A

Termination Style

Solder Pad

Connector Type

Micro USB Type B Receptacle

Color

Black

Features

Without Locking Feature

Flammability Rating

UL 94 V-0

Insulation Resistance

100 MOhms

Mounting Angle

Right

Number Of Positions / Contacts

5

Operating Temperature Range

0 C to + 50 C

Voltage Rating

30 VAC

Size

Micro

Orientation

Right Angle

Mount Location

Top

Termination Method

Surface Mount

Locking Feature

Without

Led

Without

Panel Ground

Without

Pcb Mount Retention Type

SMT Hold Down

Shell Plating

Reflowed Tin over Nickel

Assembly Process Feature

Without Pick and Place Cover

Locating Post(s)

Without

Number Of Positions

5

Contact Termination Type

Surface Mount

Contact Plating, Mating Area, Material

Gold

Contact Plating, Mating Area, Thickness (µm [?in])

0.762 [30]

Housing Color

Black

Industry Standard

USB 2.0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Reflow solder capable to 245°C

Rohs/elv Compliance History

Always was RoHS compliant

Usb-if Test Id Number (tid)

60001336

Applies To

Printed Circuit Board

Pcb Thickness, Recommended (mm [in])

1.00 [0.039]

Packaging Method

Tape & Reel

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

1981568-1

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

1981568-1

Manufacturer:

TE

Quantity:

20 000

58

Products for Mobile Equipment

Antenna Products

Antenna Manufacturing Capabilities

Three Key Technologies

MID (Molded Interconnect Device) Antennas

In 2000, Tyco Electronics acquired Molded Interconnect Device, LLC (MID). Now part of Tyco

Electronics Antenna Products, MID is headquartered in Rochester, NY and prides itself in being the

world’s leader in utilizing its technology to make everyday products better. With over 500 million

parts in service, our products are being utilized in applications ranging from joysticks to cell phones

as well as minivans to airplanes. In its most basic form, MID technology can be defined as any

product that results in selectively plated plastic parts. This technology results in outstanding repeat-

ability, which is ultimately suitable for the design and production of complex shaped antennas.

Stamped Metal and Overmolded

Tyco Electronics Antenna products has developed a line of low profile, high performance

Stamped Metal embedded antenna solutions for single-, dual-, tri-and quad-band applications.

Tyco Electronics Stamped Metal antennas offer OEMs, a low cost and highly repeatable manu-

facturing solution, in a number of standard “of the shelf” and customized antenna designs. Our

stamped embedded antennas address the needs of a variety of applications from 400 MHz to

5 GHz such as; mobile phones (AMPS, TDMA, CDMA, WCDMA, PCS, DCS and GSM), cordless

telephones, personal digital assistants (PDA), laptop computers, global positioning system (GPS)

devices and wireless networking (Bluetooth, 802.11 and ISM).

All specifications subject to change. Consult Tyco Electronics for latest specifications.

MID Two Shot Antennas

■

■

■

■

■

■

■

■

■

Stamped Antennas

■

■

■

■

■

■

■

Design flexibility for 3D patterning

Fewest manufacturing steps and processes

Repeatability of manufacturing process

Ability to integrate multiple functions

Flexible manufacturing capacity

Manageability of demand increases

Simple low cost standardized interconnect utilized

Best utilization of the 3D space that is available

Tightest tolerances for pattern registration

Stamped and heatstaked

Stamped and overmolded

Pure stampings

Typically the lowest cost antenna technology

when considering the interconnect cost as well

Interconnect can be designed in (contacts)

Production die is high volume capable

Hand assembly stations can be added for volume

upswings

Catalog 1654270-2

Revised 8-2007