1469025-2 TE Connectivity, 1469025-2 Datasheet - Page 3

1469025-2

Manufacturer Part Number

1469025-2

Description

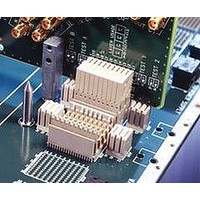

Conn Backplane HDR 40 POS 2.5mm Press Fit ST Thru-Hole

Manufacturer

TE Connectivity

Type

Backplaner

Series

Z-PACKr

Specifications of 1469025-2

Pitch

2.5 mm

Number Of Rows

4

Number Of Contacts

40

Termination Method

Press Fit

Mounting

Through Hole

Contact Plating

Gold Over Nickel

Connector Type

Hard Metric (HM)

Row Pitch

2mm

Pitch Spacing

2mm

No. Of Contacts

40

Gender

Header

Contact Termination

Press Fit

No. Of Rows

4

Rohs Compliant

Yes

Product Type

Male

Number Of Positions / Contacts

40

Termination Style

Press Fit

Housing Material

Polyester, Glass Filled

Contact Material

Copper Nickel Silicon

Mounting Style

Through Hole

Pcb Mounting Orientation

Vertical

Shield Material

Phosphor bronze

Module Length (mm [in])

24.90 [0.980]

Interface Type

HM-Zd

Termination End Plating

Tin-Lead over Nickel

Card Slot Pitch (mm [in])

20.3 [0.8]

Columns Per Connector

10

Centerline (mm [in])

2.50 [0.098]

Selectively Loaded

No

Number Of Positions

40

Contact Type

Pin

Contact Termination Type

Through Hole

Contact Configuration

ACTION PIN Post

Feedthrough Post Length (mm [in])

2.50 [0.098]

Contact Mating Area Length (mm [in])

3.80 [0.150]

Contact Base Material

Phosphor Bronze

Number Of Pairs Per Column

2

Number Of Pairs Per Connector

20

Sequenced Pins

No

Advancedtca Specified Product

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Lead Free Status / Rohs Status

Details

Rev C

W ithstanding voltage.

Tem perature rise vs current.

Vibration, random .

Mechanical shock.

Durability.

Mating force.

Unm ating force.

Test Description

1 m inute hold with no breakdown or

flashover.

30°C m axim um tem perature rise at

.7 am pere per contact, fully

energized.

No discontinuities of 1 m icrosecond

or longer duration.

See Note.

No discontinuities of 1 m icrosecond

or longer duration.

See Note.

See Note.

0.38 N [.085 lbf] m axim um average

per m ated contact. “m ated contact”

refers to signal pins and ground

blades, i.e., each signal pin = 1

contact and each ground blade = 1

contact.

0.15 N [.03 lbf] m inim um average

per contact (applies to both signal

and ground contacts).

Figure 1 (continued)

MECHANICAL

Requirem ent

EIA-364-20, Condition I.

650 volts AC at sea level between

m ated pairs of signal contacts.

550 volts AC at sea level between

m ated ground and signal contacts.

Test between adjacent signal

contacts, and closest signal and

ground contact.

EIA-364-70, Method 1.

Stabilize at a single current level

until 3 readings at 5 m inute

intervals are within 1°C.

EIA-364-28, Test Condition VII,

Condition D.

Subject m ated specim ens to 3.10

G's rm s between 20-500 Hz. 15

m inutes in each of 3 m utually

perpendicular planes.

See Figure 4.

EIA-364-27, Method A.

Subject m ated specim ens to

490m /s (50 G's) half-sine shock

pulses of 11 m illiseconds duration.

3 shocks in each direction applied

along 3 m utually perpendicular

planes, 18 total shocks.

See Figure 4.

EIA-364-9.

Mate and unm ate specim ens for

250 cycles at a m axim um rate of

600 cycles per hour.

EIA-364-13.

Measure force necessary to m ate

specim ens at a m axim um rate of

12.7 m m [.5 in] per m inute.

EIA-364-13.

Measure force necessary to

unm ate specim ens at a m axim um

rate of 12.7 m m [.5 in] per m inute.

2

Procedure

108-2055

3 of 8