1469025-2 TE Connectivity, 1469025-2 Datasheet - Page 6

1469025-2

Manufacturer Part Number

1469025-2

Description

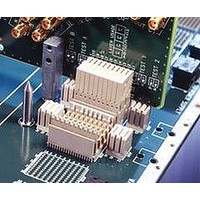

Conn Backplane HDR 40 POS 2.5mm Press Fit ST Thru-Hole

Manufacturer

TE Connectivity

Type

Backplaner

Series

Z-PACKr

Specifications of 1469025-2

Pitch

2.5 mm

Number Of Rows

4

Number Of Contacts

40

Termination Method

Press Fit

Mounting

Through Hole

Contact Plating

Gold Over Nickel

Connector Type

Hard Metric (HM)

Row Pitch

2mm

Pitch Spacing

2mm

No. Of Contacts

40

Gender

Header

Contact Termination

Press Fit

No. Of Rows

4

Rohs Compliant

Yes

Product Type

Male

Number Of Positions / Contacts

40

Termination Style

Press Fit

Housing Material

Polyester, Glass Filled

Contact Material

Copper Nickel Silicon

Mounting Style

Through Hole

Pcb Mounting Orientation

Vertical

Shield Material

Phosphor bronze

Module Length (mm [in])

24.90 [0.980]

Interface Type

HM-Zd

Termination End Plating

Tin-Lead over Nickel

Card Slot Pitch (mm [in])

20.3 [0.8]

Columns Per Connector

10

Centerline (mm [in])

2.50 [0.098]

Selectively Loaded

No

Number Of Positions

40

Contact Type

Pin

Contact Termination Type

Through Hole

Contact Configuration

ACTION PIN Post

Feedthrough Post Length (mm [in])

2.50 [0.098]

Contact Mating Area Length (mm [in])

3.80 [0.150]

Contact Base Material

Phosphor Bronze

Number Of Pairs Per Column

2

Number Of Pairs Per Connector

20

Sequenced Pins

No

Advancedtca Specified Product

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Lead Free Status / Rohs Status

Details

4.

4.1.

4.2.

4.3.

4.4.

Rev C

B.

QUALITY ASSURANCE PROVISIONS

Qualification Testing

A.

B.

Requalification Testing

If changes significantly affecting form , fit or function are m ade to the product or m anufacturing process,

product assurance shall coordinate requalification testing, consisting of all or part of the original testing

sequence as determ ined by developm ent/product, quality and reliability engineering.

Acceptance

Acceptance is based on verification that the product m eets the requirem ents of Figure 1. Failures

attributed to equipm ent, test setup, operator deficiencies, or applied non-Tyco com ponent(s) shall not

disqualify the product. If product failure occurs, corrective action shall be taken and specim ens

resubm itted for qualification. Testing to confirm corrective action is required before resubm ittal.

Quality Conform ance Inspection

The applicable quality inspection plan shall specify the sam pling acceptable quality level to be used.

Dim ensional and functional requirem ents shall be in accordance with the applicable product drawing

and this specification.

Four Pair HM-Zd Connectors (right angle receptacle, right angle header)

Specim en Selection

Specim ens shall be prepared in accordance with applicable Instruction Sheets and shall be

selected at random from current production. All test groups shall each consist of a m inim um of 4

specim ens.

Test Sequence

Qualification inspection shall be verified by testing specim ens as specified in Figure 2.

NOTE

(a)

(b)

See paragraph 4.1.A.

Numbers indicate sequence in which tests are performed.

Low level contact resistance

Vibration

Mechanical shock

Tem perature rise vs current

Test or Exam ination

Figure 2B

Test Sequence (b)

1,3,5

Test Group (a)

1

2

4

2

1

108-2055

6 of 8