1213860-1 Tyco Electronics, 1213860-1 Datasheet - Page 4

1213860-1

Manufacturer Part Number

1213860-1

Description

CERTI-CRIMP II ADAPT-SDE BENCH

Manufacturer

Tyco Electronics

Series

Certi-Crimp™r

Datasheet

1.1213860-1.pdf

(5 pages)

Specifications of 1213860-1

Accessory Type

Handle

Tool Type

Tool Holder Assembly

For Use With/related Products

SDE Electric Bench Terminator

Lead Free Status / RoHS Status

Not applicable / Not applicable

Features

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

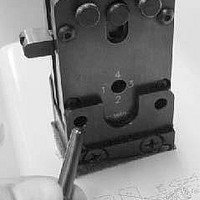

Adjust the crimp height with a flat–bladed screwdriver.

There are four different crimp heights. Refer to

Figure 6.

5. OPERATION

The tool holder assembly is used with the SDE

Electric Bench Terminator and a CERTI–CRIMP II

Crimping Head. For operating instructions, refer to

Customer Manual 409–10052.

6. PREVENTIVE MAINTENANCE AND INSPECTION

It is recommended that a maintenance and inspection

program be performed periodically to ensure

dependable and uniform terminations.

6.1. Daily Maintenance

4

DANGER

of 5

NOTE

1. Remove dust, moisture, and other contaminants

with a clean, soft brush, or a lint–free cloth. DO

NOT use objects that could damage the adapter.

2. Make sure that all components are in place and

secure.

3. Make certain all surfaces are protected with a

thin coat of any good SAE 20 motor oil. DO NOT

oil excessively.

Use a Flat-Bladed Screwdriver

Crimp Height Adjustment

(One Step Equals 0.1mm [.004 In.])

Although Tyco Electronics normally recommends

Position No. 2 (adjustment of the manufacturer),

Positions No. 3 and No. 4 increase the travel of

the tool head, which decreases the crimp height.

Position No. 1 decreases the the travel of the

head, which increases the crimp height.

To avoid personal injury, ALWAYS DISCONNECT

the SDE Electric Bench Terminator before

performing maintenance or inspection.

Figure 6

CERTI-CRIMP II Tool Holder Assembly 1213860-1

6.2. Lubrication

Lubricate all pins, pivot points, and bearing surfaces

with a high quality grease. It is recommended using

Molykote paste which is a commercially available

lubricant. Lubricate according to the following

schedule:

6.3. Visual Inspection

Regular inspections should be performed by

quality–control personnel. A record of scheduled

inspections should remain with the tool holder

assembly or be supplied to personnel responsible for

the tool holder assembly. Though recommendations

call for at least one inspection a month, the frequency

should be based on amount of use, working

conditions, operator training and skill, and established

company policies.

7. REPLACEMENT AND REPAIR

Customer–replaceable parts are listed in Figure 7.

A complete inventory should be stocked and

controlled to prevent lost time when replacement of

parts is necessary. Parts other than those listed

should be replaced by Tyco Electronics to ensure

quality and reliability. Order replacement parts

through your Tyco Electronics Representative, or call

1–800–526–5142, or send a facsimile of your

purchase order to 717–986–7605, or write to:

For customer repair service, call 1–800–526–5136.

8. REVISION SUMMARY

Initial release of 408–10021

4. When the tool holder assembly is not in use,

store it in a clean, dry area.

If the tool holder assembly is used daily—lubricate

daily

If the tool holder assembly is used

occasionally—lubricate weekly

If the tool holder assembly is used

weekly—lubricate monthly

1. Remove all lubrication and accumulated film by

immersing the tool holder assembly in a suitable

commercial degreaser that will not affect paint or

plastic.

2. Make certain all components are in place.

3. Check all bearing surfaces for wear. Replace

any worn parts. If replacements are necessary,

refer to Section 7, REPLACEMENT AND REPAIR.

CUSTOMER SERVICE (038–035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105–3608

408-10021

Rev

A