APDS-9005-020 Avago Technologies US Inc., APDS-9005-020 Datasheet - Page 9

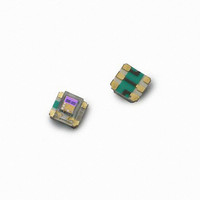

APDS-9005-020

Manufacturer Part Number

APDS-9005-020

Description

AMBIENT LIGHT SENSOR 6CHIPLED

Manufacturer

Avago Technologies US Inc.

Type

Ambient Light Photo Sensorr

Datasheet

1.APDS-9005-020.pdf

(12 pages)

Specifications of APDS-9005-020

Package / Case

Chip LED-6

Maximum Operating Temperature

+ 85 C

Mounting Style

SMD/SMT

Product

Ambient Light Sensor

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

516-1717-2

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

APDS-9005-020

Manufacturer:

OSRAM

Quantity:

30 000

Recommended Reflow Profile

The reflow profile is a straight-line representation of a nominal temperature profile for a convective reflow solder

process. The temperature profile is divided into four process zones, each with different DT/Dtime temperature change

rates or duration. The DT/Dtime rates or duration are detailed in the above table. The temperatures are measured at

the component to printed circuit board connections.

Process zone P1, the PC board and APDS-9005 pins are heated to a temperature of 150°C to activate the flux in the

solder paste. The temperature ramp up rate, R1, is limited to 3°C per second to allow for even heating of both the PC

board and APDS-9005 pins.

Process zone P2 should be of sufficient time duration (100 to 180 seconds) to dry the solder paste. The temperature is

raised to a level just below the liquidus point of the solder, usually 200°C (392°F).

Process zone P3 is the solder reflow zone. In zone P3, the temperature is quickly raised above the liquidus point of

solder to 255°C (491°F) for optimum results. The dwell time above the liquidus point of solder should be between 20

and 40 seconds. It usually takes about 20 seconds to assure proper coalescing of the solder balls into liquid solder and

the formation of good solder connections. Beyond a dwell time of 40 seconds, the intermetallic growth within the

solder connections becomes excessive, resulting in the formation of weak and unreliable connections. The tempera-

ture is then rapidly reduced to a point below the solidus temperature of the solder, usually 200°C (392°F), to allow the

solder within the connections to freeze solid.

Process zone P4 is the cool down after solder freeze. The cool down rate, R5, from the liquidus point of the solder to

25°C (77°F) should not exceed 6°C per second maximum. This limitation is necessary to allow the PC board and APDS-

9005 pins to change dimensions evenly, putting minimal stresses on the APDS-9005.

It is recommended to perform reflow soldering no more than twice.

9

150

120

230

217

180

255

200

25

80

Process Zone

Heat Up

Solder Paste Dry

Solder Reflow

Cool Down

Time maintained above °C

Peak Temperature

Time within 5°C of actual Peak Temperature

Time 5°C to Peak Temperature

0

R1

HEAT

P1

UP

50

SOLDER PASTE DRY

R2

100

Symbol

P, R

P, R

P3, R3

P3, R4

P4, R5

P2

150

50°C to 00°C

00°C to 55°C

55°C to 00°C

5°C to 50°C

00°C to 5°C

5°C to 60°C

> °C

> 55°C

60°C

DT

R3

60 sec to 90 sec

Above 217˚C

MAX 260˚C

200

REFLOW

SOLDER

P3

Maximum DT/Dtime

R4

00s to 80s

or Duration

60s to 90s

0s to 40s

COOL DOWN

-6°C/s

-6°C/s

8mins

3°C/s

3°C/s

250

P4

R5

300

t-TIME

(SECONDS)