SI8401DB-T1-E1 Vishay, SI8401DB-T1-E1 Datasheet - Page 8

SI8401DB-T1-E1

Manufacturer Part Number

SI8401DB-T1-E1

Description

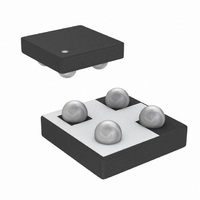

P CH MOSFET, -20V, 4.9A, MICRO FOOT

Manufacturer

Vishay

Series

TrenchFET®r

Specifications of SI8401DB-T1-E1

Transistor Polarity

P Channel

Continuous Drain Current Id

-4.9A

Drain Source Voltage Vds

-20V

On Resistance Rds(on)

95mohm

Rds(on) Test Voltage Vgs

12V

Threshold Voltage Vgs Typ

1.4V

Fet Type

MOSFET P-Channel, Metal Oxide

Fet Feature

Logic Level Gate

Rds On (max) @ Id, Vgs

65 mOhm @ 1A, 4.5V

Drain To Source Voltage (vdss)

20V

Current - Continuous Drain (id) @ 25° C

3.6A

Vgs(th) (max) @ Id

1.4V @ 250µA

Gate Charge (qg) @ Vgs

17nC @ 4.5V

Power - Max

1.47W

Mounting Type

Surface Mount

Package / Case

4-MICRO FOOT®CSP

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

SI8401DB-T1-E1TR

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

SI8401DB-T1-E1

Manufacturer:

VISHAY/威世

Quantity:

20 000

Á Á Á

Á Á Á

Á Á Á

Á Á Á

Á Á Á

Á Á Á

Á Á Á

Board pad design. The landing-pad size for MICRO FOOT

products is determined by the bump pitch as shown in Table 3.

The pad pattern is circular to ensure a symmetric,

barrel-shaped solder bump.

ASSEMBLY PROCESS

MICRO FOOT products’ surface-mount-assembly operations

include solder paste printing, component placement, and

solder reflow as shown in the process flow chart (Figure 5).

Stencil design. Stencil design is the key to ensuring

maximum solder paste deposition without compromising the

assembly yield from solder joint defects (such as bridging and

extraneous solder spheres). The stencil aperture is dependent

on the copper pad size, the solder mask opening, and the

quantity of solder paste.

In MICRO FOOT products, the stencil is 0.125-mm (5-mils)

thick. The recommended apertures are shown in Table 3 and

are fabricated by laser cut.

Solder-paste printing. The solder-paste printing process

involves transferring solder paste through pre-defined

apertures via application of pressure.

In MICRO FOOT products, the solder paste used is UP78

No-clean eutectic 63 Sn/37Pb type3 or finer solder paste.

Document Number: 71990

06-Jan-03

0.80 mm

0.50 mm

Pitch

Dimensions of Copper Pad and Solder Mask

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Opening in PCB and Stencil Aperture

Copper Pad

0.30 " 0.01 mm

0.17 " 0.01 mm

FIGURE 5. SMT Assembly Process Flow

IIncoming Tape and Reel Inspection

Solder Joint Inspection

Solder Paste Printing

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

TABLE 3

Chip Placement

Pack and Ship

Stencil Design

Solder Mask

0.41 " 0.01 mm

0.27 " 0.01 mm

Opening

Reflow

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

Á Á Á Á Á

in square aperture

in ciircle aperture

0.33 " 0.01 mm

0.30 " 0.01 mm

Aperture

Stencil

Chip pick-and-placement. MICRO FOOT products can be

picked and placed with standard pick-and-place equipment.

The recommended pick-and-place force is 150 g. Though the

part will self-center during solder reflow, the maximum

placement offset is 0.02 mm.

Reflow Process. MICRO FOOT products can be assembled

using standard SMT reflow processes. Similar to any other

package, the thermal profile at specific board locations must

be determined. Nitrogen purge is recommended during reflow

operation. Figure 6 shows a typical reflow profile.

PCB REWORK

To replace MICRO FOOT products on PCB, the rework

procedure is much like the rework process for a standard BGA

or CSP, as long as the rework process duplicates the original

reflow profile. The key steps are as follows:

1.

2.

3.

4.

5.

6.

Apply gel flux to the pad.

Remove the MICRO FOOT device using a convection

nozzle to create localized heating similar to the original

reflow profile. Preheat from the bottom.

Once the nozzle temperature is +190_C, use tweezers to

remove the part to be replaced.

Resurface the pads using a temperature-controlled

soldering iron.

Use a vacuum needle pick-up tip to pick up the

replacement part, and use a placement jig to placed it

accurately.

Reflow the part using the same convection nozzle, and

preheat from the bottom, matching the original reflow

profile.

250

200

150

100

50

0

0

FIGURE 6. Reflow Profile

100

Thermal Profile

Time (Seconds

200

Vishay Siliconix

300

www.vishay.com

AN824

400

3