MBRB3030CTLG ON Semiconductor, MBRB3030CTLG Datasheet - Page 5

MBRB3030CTLG

Manufacturer Part Number

MBRB3030CTLG

Description

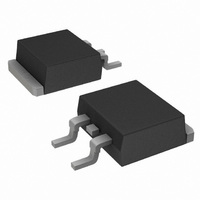

DIODE SCHOTTKY 30V 15A D2PAK

Manufacturer

ON Semiconductor

Series

SWITCHMODE™r

Datasheet

1.MBRB3030CTLG.pdf

(8 pages)

Specifications of MBRB3030CTLG

Voltage - Forward (vf) (max) @ If

440mV @ 15A

Current - Reverse Leakage @ Vr

2mA @ 30V

Current - Average Rectified (io) (per Diode)

15A

Voltage - Dc Reverse (vr) (max)

30V

Diode Type

Schottky

Speed

Fast Recovery =< 500ns, > 200mA (Io)

Diode Configuration

1 Pair Common Cathode

Mounting Type

Surface Mount

Package / Case

D²Pak, TO-263 (2 leads + tab)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Reverse Recovery Time (trr)

-

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

MBRB3030CTLG

Manufacturer:

ON

Quantity:

12 500

Part Number:

MBRB3030CTLG

Manufacturer:

ON/安森美

Quantity:

20 000

Suggested Method of Characterization

tested to failure using inductors ranging in value from 0.01

to 159 mH. The reverse voltage and current waveforms are

acquired to determine the exact energy seen by the device

and the inductive current decay time. At least 4 distinct

inductors and 5 to 10 devices per inductor are used to

generate the characteristic current versus time relationship.

This relationship when coupled with the application circuit

conditions, defines the SOA of the device uniquely for this

application.

Utilizing the UIS test circuit in Figure 10, devices are

Figure 11. Typical Voltage and Current UIS

INDUCTOR

CURRENT

Waveforms

TIME (s)

DUT

REVERSE

VOLTAGE

http://onsemi.com

MBRB3030CTL

5

Example Application

which is a 30 A (15 A per side) forward current, 35 V reverse

breakdown voltage rectifier. All parts were tested to

destruction at 25°C. The inductors used for the

characterization were 10, 3.0, 1.0 and 0.3 mH. The data

recorded from the testing were peak reverse current (Ip),

peak reverse breakdown voltage (BVR), maximum

withstand energy, inductance and inductor discharge time

(see Table 1). A plot of the Peak Reverse Current versus

Time at device destruction, as shown in Figure 12, was

generated. The area under the curve is the region of lower

reverse energy or lower stress on the device. This area is

known as the safe operating area or SOA.

120

100

80

60

40

20

The device used for this example was an MBR3035CT,

0

0

SAFE OPERATING AREA

Figure 12. Peak Reverse Current versus

0.0005 0.001 0.0015 0.002 0.0025

UIS CHARACTERIZATION CURVE

Time for DUT

TIME (s)

0.003 0.0035 0.004