5536603-1 TE Connectivity, 5536603-1 Datasheet - Page 51

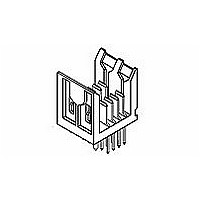

5536603-1

Manufacturer Part Number

5536603-1

Description

Conn Backplane HDR 8Power POS 2mm Press Fit ST Thru-Hole

Manufacturer

TE Connectivity

Type

Backplaner

Series

5536603r

Datasheet

1.1645499-5.pdf

(52 pages)

Specifications of 5536603-1

Pitch

2 mm

Number Of Rows

4

Number Of Contacts

8Power

Termination Method

Press Fit

Mounting

Through Hole

Contact Plating

Gold Over Nickel|Gold Over Palladium Nickel Over Nickel

Rohs Compliant

YES

Number Of Positions / Contacts

8

Mounting Angle

Vertical

Mounting Style

Press Fit

Termination Style

Pin

Housing Material

Liquid Crystal Polymer

Contact Material

Phosphor Bronze

Product Type

Connector

Connector Type

Header

Pcb Mounting Orientation

Vertical

Post Type

Press-Fit

Make First / Break Last

No

Module Type

Power

Number Of Power Positions

8

Pin Header Width (mm [in])

16.00 [0.622]

Voltage Rating (vac)

30

Sequencing

Yes

Sequencing Configuration Row A

Mating Post Length 6.5mm, Termination Post Length 4.25mm

Sequencing Configuration Row B

Mating Post Length 6.5mm, Termination Post Length 4.25mm

Sequencing Configuration Row C

Mating Post Length 6.5mm, Termination Post Length 4.25mm

Sequencing Configuration Row D

Mating Post Length 6.5mm, Termination Post Length 4.25mm

Post Plating

Tin

Centerline, Matrix (mm [in])

2.00 x 2.00 [.079 x .079]

Contact Type

Pin

Contact Base Material

Phosphor Bronze

Contact Plating, Mating Area, Material

Gold (30)

Connector Style

Plug

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Printed Circuit Board

Application

Fixed-Board

Lead Free Status / Rohs Status

Details

60

Product Facts

■

■

■

■

■

■

■

■

■

Technical Documents

Product Specification

108-2216

Application Specification

114-13156

Industry Standard

PICMG 3.0, Rev. 2.0

AdvancedTCA and PICMG are

trademarks of the PICMG-PCI Industrial

Computer Manufacturers Group, Inc.

Catalog 1773096

Revised 2-10

www.tycoelectronics.com

Designed to PICMG 3.0

Standard

High conductivity copper

alloy on Size 16 power

contacts

.76 micro-meters

[30 microinch] gold over

1.27 micrometers

[50 microinch] nickel

plating at contact interface

Gold-thickness controlled on

inside of socket and outside

of pin — at contact interface

points

RoHS compliant

Stainless steel spring

provides contact normal

force — resists relaxation at

elevated temperatures

Eye of the needle compliant

press-fit termination

No special tools needed to

seat connectors to PCB —

standard Flat-Rock seating

tools

Additional PCB retention

hardware not required

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Power Connectors & Interconnection Systems

Z1 Power Connector for AdvancedTCA Zone 1 Applications

Introduction

Tyco Electronics supplies

both the power and the

signal connectors

specified in the Advanced

Telecommunications

Computer Architecture

(AdvancedTCA) Standard.

This standard (PICMG 3.0)

is one of the latest stan-

dards addressing future

telecommunications needs.

The AdvancedTCA Power

Connector, designated for

use in Zone 1 per PICMG

3.0, combines 8 High

Conductivity Size 16 pin &

socket contacts along with

22 Size 22 pin & socket

contacts, plus guidance

into a compact interface.

Both connector halves

feature proven compliant

press-fit contacts for easy

solder-less termination to

printed circuit boards.

Based on years of reliable

long-term field installations

the power contact design is

based upon Tyco Electronics’

famous Type III+ contact

design. By adding the use

of a high conductivity cop-

per alloy and the low-force

Eye-Of-Needle compliant

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

pin section, the new con-

tact delivers both ease of

installation (with flat-rock

seating tools) as well as

industry-leading current

carrying capability. The

power contacts are capable

of carrying 20 amps per

contact and the signals are

capable of carrying 2 amps

per contact.

The housing design also

offers improvements com-

pared to other industry

alternatives. The lead-in

design for the contact

cavities provides better

resistance from contact

stubbing. The contact

retention has also been

designed to eliminate the

need for additional hard-

ware sometimes used to

hold the connectors to

the PCB after pressing in to

the PCB.

The result is a connector

which is easy to install,

meets all the PICMG 3.0

performance requirements

and stays retained to the

PCB without the additional

labor required to add

hardware.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-1106-0803

Typical Electrical Properties

Current Ratings — tested in

accordance with CSA C22.2 No.

182.3-M1987 and IEC 60512-3, Test 5a

requirements:

Positions 1–24, 27, 32 — 1 Amp each,

per the PICMG 3.0 Specification

Positions 25, 26, 28–31, and 34 —

20 Amps each, exceeds the PICMG 3.0

Specification

Dielectric Withstanding Voltage —

Positions 1–16 — 1000 Volts rms

Positions 17–24 — 2000 Volts rms

Positions 25–34 — 2000 Volts rms

Environmental Parameters

Maximum Continuous Operating

Temperature — 105°C

Durability Rating — 250 cycles, per

PICMG 3.0

South America: 55-11-2103-6000

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-(0)8002-67666

METRIC

millimeters over inches

Dimensions are