PKS606FN Power Integrations, PKS606FN Datasheet - Page 9

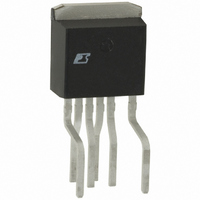

PKS606FN

Manufacturer Part Number

PKS606FN

Description

IC OFFLINE SWIT OTP OCP HV TO262

Manufacturer

Power Integrations

Series

PeakSwitch®r

Specifications of PKS606FN

Mfg Application Notes

PeakSwitch Design Guide AppNote

Output Isolation

Isolated

Frequency Range

250 ~ 304kHz

Voltage - Output

700V

Power (watts)

117W

Operating Temperature

-40°C ~ 150°C

Package / Case

TO-262-7 (Formed Leads), 5 Leads

Output Voltage

12 V

Input / Supply Voltage (max)

265 VAC

Input / Supply Voltage (min)

85 VAC

Duty Cycle (max)

65 %

Switching Frequency

47 KHz

Supply Current

25 uA

Operating Temperature Range

- 40 C to + 150 C

Mounting Style

Through Hole

For Use With

596-1198 - KIT REF DESIGN 36-72W MOTOR DRVR

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

596-1125-5

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

PKS606FN

Manufacturer:

power

Quantity:

15 000

Part Number:

PKS606FN

Manufacturer:

POWER

Quantity:

20 000

Primary Inductance Tolerance, L

This is the assumed primary inductance tolerance. A value of

12% is used by default. However, if specific information is

known from the transformer vendor, then this may be entered

in the grey override cell.

Number of Primary Turns, N

Total number of primary turns. For low leakage inductance it

is recommended that split primary construction be used.

Gapped core effective inductance, A

transformer vendor to specify the core gap.

Target B

The value entered here is used to calculate the number of

secondary turns. By default, a value of 2800 Guass is used,

slightly below the recommended maximum B

3000 Gauss. This accounts for the rounding down of the number

of calculated secondary turns in some designs.

Maximum Operating Flux Density, B

A maximum value of 3000 Gauss during normal operation is

recommended to limit the maximum flux density under start

up and output short circuit. Under these conditions, the output

voltage is low and little reset of the transformer occurs during

the MOSFET off time. This may allow the transformer flux

density to staircase above the normal operating level. A value

of 3000 Gauss at the peak current limit of the selected device,

together with the built-in protection features of PeakSwitch

provides sufficient margin to prevent core saturation under

startup or output short circuit conditions.

Figure 12. Transformer Primary Design Section of Design Spreadsheet.

Figure 13. Transformer Secondary Primary Parameters Section of Design Spreadsheet – Lumped into Single Output.

TRANSFORMER PRIMARY DESIGN PARAMETERS

LP

LP_TOLERANCE

NP

ALG

Target BM

BM

BAC

ur

LG

BWE

OD

INS

DIA

AWG

CM

CMA

TRANSFORMER SECONDARY DESIGN PARAMETERS

Lumped parameters

ISP

ISRMS

IRIPPLE

CMS

AWGS

M

(Gauss)

P

P_TOLERANCE

LG

M

(nH/T

(Gauss)

(%)

2

) used by the

M

value of

2800 Gauss

2624 Gauss

1588

0.28 mm

23.7 mm

0.33 mm

0.06 mm

0.28 mm

3.34 Amps

1.74 Amps

1.57 Amps

367 uHenries

789 Gauss

102 Cmils

208 Cmils/Amp Primary Winding Current Capacity (100 < CMA < 500)

349 Cmils

12 %

71

72 nH/T^2

30 AWG

24 AWG

The cycle skipping mode of operation used in PeakSwitch

can produce audio frequency displacements in the

transformer. To limit this noise, the transformer should

be designed such that the peak core flux density is below

3000 Gauss (300 mT). Following this guideline and using the

standard transformer production technique of dip varnishing

practically eliminates audible noise. A careful evaluation of the

audible noise performance should be made, using production

transformer samples before approving the design. When

ceramic capacitors that have Z5U dielectrics are used in clamp

circuits, they too may produce audible sound. They should be

replaced with capacitors that have a different dielectric, such

as polyester film.

Maximum Primary Wire Diameter, OD (mm)

By default, if the override cell is empty, double coated wire

is assumed and a standard wire diameter is chosen. The grey

override cells can be used to enter a wire diameter directly.

Primary wire size, DIA: (mm)

Primary wire gauge, AWG

Number of primary layers, L

Estimated core center leg gap length: L

Number of secondary turns, N

Secondary wire size, DIA

Secondary wire gauge, AWG

In multiple output designs N

output number) should also be used.

Peak Secondary Current

Secondary RMS Current

Output Capacitor RMS Ripple Current

Secondary Bare Conductor minimum circular mils

Secondary Wire Gauge (Rounded up to next larger standard

AWG value)

Typical Primary Inductance. +/- 12% to ensure a minimum

primary inductance of 328 uH

Primary inductance tolerance

Primary Winding Number of Turns

Gapped Core Effective Inductance

Target Peak Flux Density at Maximum Current Limit

Calculated Maximum Operating Flux Density, BM < 3000 is

recommended

AC Flux Density for Core Loss Curves (0.5 X Peak to Peak)

Relative Permeability of Ungapped Core

Gap Length (Lg > 0.1 mm)

Effective Bobbin Width

Maximum Primary Wire Diameter including insulation

Estimated Total Insulation Thickness (= 2 * film thickness)

Bare conductor diameter

Primary Wire Gauge (Rounded to next smaller standard AWG

value)

Bare conductor effective area in circular mils

S

: (mm)

Sx

S

S

, CM

Sx

AN-41

, AWG

g

: (mm)

Sx

(where x is the

Rev. E 02/07