LMD18400N/NOPB National Semiconductor, LMD18400N/NOPB Datasheet - Page 9

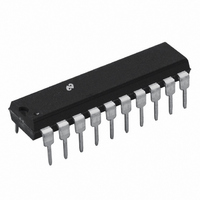

LMD18400N/NOPB

Manufacturer Part Number

LMD18400N/NOPB

Description

IC DRIVER QUAD HI SIDE 20-DIP

Manufacturer

National Semiconductor

Datasheet

1.LMD18400NNOPB.pdf

(19 pages)

Specifications of LMD18400N/NOPB

Configuration

High-Side

Input Type

Non-Inverting

Delay Time

5µs

Current - Peak

3A

Number Of Configurations

4

Number Of Outputs

4

Voltage - Supply

7 V ~ 28 V

Operating Temperature

-25°C ~ 85°C

Mounting Type

Through Hole

Package / Case

20-DIP (0.300", 7.62mm)

Supply Voltage Min

7V

Supply Voltage Max

60V

No. Of Outputs

4

Output Voltage

5.5V

Output Current

3.75A

Driver Case Style

DIP

Msl

MSL 1 - Unlimited

Device Type

High Side

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

High Side Voltage - Max (bootstrap)

-

Other names

*LMD18400N

*LMD18400N/NOPB

LMD18400N

*LMD18400N/NOPB

LMD18400N

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LMD18400N/NOPB

Manufacturer:

National Semiconductor

Quantity:

135

Applications Information

1.3Ω (the ON resistance of the DMOS switch). The voltage

applied to the load will depend upon the load current and the

designed current capability of the LMD18400. When a switch

is commanded OFF, the load will be disconnected from the

supply except for a small leakage current of typically less

than 0.01 µA.

The LMD18400 can be continually connected to a live power

source, a car battery for example, while drawing less than

10 µA from the power source when put into a “sleep” condi-

tion. This “sleep” mode is enacted by taking the Enable Input

(pin 3) low. During this mode the supply current for the

device is typically only 0.04 µA. Special low current con-

sumption standby circuitry is used to hold the DMOS

switches OFF to eliminate the possibility of supply voltage

transients from turning on any of the loads (a common

problem with MOS power devices). When in the “sleep”

mode, all diagnostic and logic circuitry is inactive. When the

Enable Input is taken to a logic 1, the switches become

“armed” and ready to respond to their control input after a

short, 30 µs, enable delay time. This delay interval prevents

the switches from transient turn-on. Figure 2 shows the

switch control logic.

Each DMOS switch is turned ON when its gate is driven

approximately 3.5V more positive than its source voltage.

Because the source of the switch is the output terminal to the

load it can be taken to a voltage very near the V

potential. To ensure that there is sufficient voltage available

to drive the gates of the DMOS device a charge pump circuit

is built in. This circuit is controlled by an internal 300 kHz

oscillator and using an external 10 nF capacitor connected

from pin 14 to ground generates a voltage that is approxi-

mately 20V greater than the V

vides sufficient gate voltage drive for each of the switches

which is applied under command of standard 5V logic input

levels.

The turn-on time for each switch is approximately 12 µs

when driving a 1A load current. This relatively slow switching

time is beneficial in minimizing electromagnetic interference

(EMI) related problems created from switching high current

levels.

FIGURE 2. Control Logic for Each Power Switch

CC

supply voltage. This pro-

(Continued)

CC

supply

01102611

9

PROTECTION CIRCUITRY

The LMD18400 has extensive protection circuitry built in.

With any power device, protection against excessive volt-

age, current and temperature conditions is essential. To

achieve a “fail-safe” system implementation, the loads are

deactivated automatically by the LMD18400 in the event of

any detected overvoltage or over-temperature fault condi-

tions.

Voltage Protection

The V

any damage to the LMD18400. The CMOS logic circuitry is

biased from an internal 5.1V regulator which protects these

lower voltage transistors from the higher V

order to protect the loads connected to the switch outputs

however, an overvoltage shutdown circuit is employed.

Should the V

turned OFF thereby disconnecting the loads. This 35V

threshold has 750 mV of hysteresis to prevent potential

oscillations.

Additionally, there is an undervoltage lockout feature built in.

With V

logic circuitry can hold the switches in their commanded

state. To avoid this uncertainty, all of the switches are turned

OFF when V

illustrates the shutoff of an output during a 0V to 80V V

supply transient.

The LMD18400 has been designed to drive all types of

loads. When driving a ground referenced inductive load such

as a relay or solenoid, the voltage across the load will

reverse in polarity as the field in the inductor collapses when

the power switch is turned OFF. This will pull the output pin

of the LMD18400 below ground. This negative transient

voltage is clamped at approximately −5V to protect the IC.

This clamping action is not done with diodes but rather the

power DMOS switch turning back on momentarily to conduct

the inductor current as it de-energizes as shown in Figure 4.

FIGURE 3. Overvoltage/Undervoltage Shutdown

CC

CC

supply can range from −0.5V to +60 V

less than 5V it becomes uncertain whether the

CC

CC

potential exceed 35V all of the switches are

drops below approximately 5V. Figure 3

Voltage Shutdown

Over/Under

CC

01102612

potentials. In

www.national.com

DC

without

CC