SSM2315-EVALZ Analog Devices Inc, SSM2315-EVALZ Datasheet - Page 4

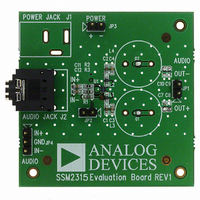

SSM2315-EVALZ

Manufacturer Part Number

SSM2315-EVALZ

Description

BOARD EVAL SSM2315

Manufacturer

Analog Devices Inc

Specifications of SSM2315-EVALZ

Amplifier Type

Class D

Output Type

1-Channel (Mono)

Max Output Power X Channels @ Load

4.28W x 1 @ 3 Ohm

Voltage - Supply

2.5 V ~ 5.5 V

Operating Temperature

-40°C ~ 85°C

Board Type

Fully Populated

Utilized Ic / Part

SSM2315

Silicon Manufacturer

Analog Devices

Application Sub Type

Audio Power Amplifier - Class D

Kit Application Type

Amplifier

Silicon Core Number

SSM2315

Kit Contents

Board

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

EVAL-SSM2315

Table 1. Recommended Output Beads (L1 and L2)

Part No.

BLM18PG121SN1D

MPZ1608S101A

MPZ1608S221A

BLM18EG221SN1D

Table 2. Recommended Output Inductors (L3 and L4)

Part No.

LQM31PNR47M00

LQM31PN1R0M00

LQM21PNR47MC0

LQM21PN1R0MC0

LQH32CN2R2M53

Output Shunting Capacitors

There are two groups of output shunting capacitors: C1, C2, C3,

and C4 work with the L1 and L2 ferrite beads; C7, C8, C9, and

C10 work with L3 and L4, if they are used. Use small size (0603

or 0402) multilayer ceramic capacitors that are made of X7R or

COG (NPO) materials. Note that the capacitors can be used in

pairs: a capacitor with small capacitance (up to 100 pF) plus a

capacitor with a larger capacitance (less than 1 nF). This config-

uration provides thorough EMI reduction for the entire frequency

spectrum. For BOM cost reduction and capable performance,

a single capacitor of approximately 470 pF can be used.

Output Inductors—L3 and L4

If you prefer using inductors for the purpose of EMI filtering

at the output nodes, choose inductance that is < 2.2 μH. The

higher the inductance, the lower the EMI is at the output.

However, the cost and power consumption by the inductors

are higher. Using 0.47 μH to 2.2 μH inductors is recom-mended,

and the current rating needs >600 mA (saturation current) for

an 8 Ω load. Table 2 shows the recommended inductors. Note

that these inductors are not populated on the evaluation board.

PCB LAYOUT GUIDELINES

To keep the EMI under the allowable limit and to ensure that

the amplifier chip operates under the temperature limit, PCB

layout is critical in application design. Figure 3 shows the

preferred layout for the SSM2315 evaluation board.

Manufacturer

Murata

TDK

TDK

Murata

Manufacturer

Murata

Murata

Murata

Murata

Murata

Rev. 0 | Page 4 of 12

Z (Ω)

120

100

220

220

0.47

0.47

L (μH)

1.0

1.0

2.2

Layer Stacks and Grounding

The stack-up for the evaluation board is a 4-layer structure.

•

•

•

•

Top layer—component layer with power and output copper

land and ground copper pouring.

Second layer—dedicated ground plane.

Third layer—dedicated power plane.

Bottom layer—bottom layer with ground copper pouring.

I

1400

1200

1100

800

790

I

2000

3000

2000

2000

Figure 3. Preferred PCB Layout for the SSM2315 Evaluation Board

MAX

MAX

GO TO VDD PLANE BY VIA

(mA)

(mA)

GO TO GND PLANE

BY VIA

0.05

0.03

0.05

0.05

DCR (Ω)

0.07

0.12

0.12

0.19

0.1

DCR (Ω)

VIA SIZE SHOULD BE

AS LARGE AS POSSIBLE

GO TO GND PLANE BY VIA

Size (mm)

1.6 × 0.8 × 0.8

1.6 × 0.8 × 0.8

1.6 × 0.8 × 0.8

1.6 × 0.8 × 0.8

Size (mm)

3.2 × 1.6 × 0.85

3.2 × 1.6 × 0.85

2.0 × 1.25 × 0.5

2.0 × 1.25 × 0.5

3.2 × 2.5 × 1.55