AD676BD Analog Devices Inc, AD676BD Datasheet - Page 9

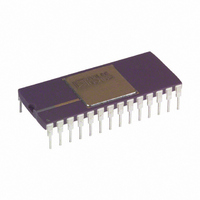

AD676BD

Manufacturer Part Number

AD676BD

Description

ADC Single SAR 100KSPS 16-Bit Parallel 28-Pin SBCDIP

Manufacturer

Analog Devices Inc

Datasheet

1.AD676JNZ.pdf

(16 pages)

Specifications of AD676BD

Package

28SBCDIP

Resolution

16 Bit

Sampling Rate

100 KSPS

Architecture

SAR

Number Of Analog Inputs

1

Digital Interface Type

Parallel

Input Type

Voltage

Polarity Of Input Voltage

Bipolar

Rohs Status

RoHS non-compliant

Number Of Bits

16

Sampling Rate (per Second)

100k

Data Interface

Parallel

Number Of Converters

2

Power Dissipation (max)

480mW

Voltage Supply Source

Analog and Digital, Dual ±

Operating Temperature

-40°C ~ 85°C

Mounting Type

Through Hole

Package / Case

28-CDIP (0.600", 15.24mm)

For Use With

AD676-EB - BOARD EVAL SAMPLING ADC AD676

Lead Free Status / RoHS Status

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

AD676BD

Manufacturer:

ADI/亚德诺

Quantity:

20 000

CONTINUOUS CONVERSION

For maximum throughput rate, the AD676 can be operated in a

continuous convert mode (see Figure 2b). This is accomplished

by utilizing the fact that SAMPLE will no longer be ignored af-

ter BUSY goes LOW, so an acquisition may be initiated even

during the HIGH time of the 17th CLK pulse for maximum

throughput rate while enabling full settling of the sample/hold

circuitry. If SAMPLE is already HIGH when BUSY goes LOW

at the end of a conversion, then an acquisition is immediately

initiated and t

ous conversion may be latched up to t

LOW or t

ever, it is preferred that latching occur on or after the falling

edge of BUSY.

Care must he taken to adhere to the minimum/maximum timing

requirements in order to preserve conversion accuracy.

GENERAL CONVERSION GUIDELINES

During signal acquisition and conversion, care should be taken

with the logic inputs to avoid digital feedthrough noise. It is pos-

sible to run CLK continuously, even during the sample period.

However, CLK edges during the sampling period, and especially

when SAMPLE goes LOW, may inject noise into the sampling

process. The AD676 is tested with no CLK cycles during the

sampling period. The BUSY signal can be used to prevent the

clock from running during acquisition, as illustrated in Figure 3.

In this circuit BUSY is used to reset the circuitry which divides

the system clock down to provide the AD676 CLK. This serves

to interrupt the clock until after the input signal has been ac-

quired, which has occurred when BUSY goes HIGH. When the

conversion is completed and BUSY goes LOW, the circuit in

Figure 3 truncates the 17th CLK pulse width which is tolerable

because only its rising edge is critical.

REV. A

12.288MHz

SYSTEM

CLOCK

OD

13

12

11

4

9

6

2

1

after the rising edge of the 17th clock pulse. How-

S

74HC175

74HC393

1D

1CLK

1QD

1CLR

3Q

CLK

2CLR

2CLK

and t

C

start from that time. Data from the previ-

CLR

2QC

2QD

2Q

1Q

3D

2D

Figure 3.

12

1

2

5

9

8

7

SD

before BUSY goes

10

7

BUSY

CLK

AD676

SAMPLE

9

–9–

Figure 3 also illustrates the use of a counter (74HC393) to de-

rive the AD676 SAMPLE command from the system clock

when a continuous convert mode is desirable. Pin 9 (2QC) pro-

vides a 96 kHz sample rate for the AD676 when used with a

12.288 MHz system clock. Alternately, Pin 8 (2QD) could be

used for a 48 kHz rate.

If a continuous clock is used, then the user must avoid CLK

edges at the instant of disconnecting V

falling edge of SAMPLE (see t

of CLK may vary, but both the HIGH (t

phases must conform to those shown in the timing specifica-

tions. The internal comparator makes its decisions on the rising

edge of CLK. To avoid a negative edge transition disturbing the

comparator’s settling, t

To also avoid transitions disturbing the internal comparator’s

settling, it is not recommended that the SAMPLE pin change

state toward the end of a CLK cycle.

During a conversion, internal dc error terms such as comparator

voltage offset are sampled, stored on internal capacitors and

used to correct for their corresponding errors when needed. Be-

cause these voltages are stored on capacitors, they are subject to

leakage decay and so require refreshing. For this reason there is

a maximum conversion time t

SAMPLE goes HIGH to the completion of the 17th CLK pulse,

no more than 1000 s should elapse for specified performance.

However, there is no restriction to the maximum time between

conversions.

Output coding for the AD676 is twos complement, as shown in

Table I. By inverting the MSB, the coding can be converted to

offset binary. The AD676 is designed to limit output coding in

the event of out-of-range inputs.

V

>Full Scale

Full Scale

Full Scale – 1 LSB

Midscale + 1 LSB

Midscale

Midscale – 1 LSB

–Full Scale + 1 LSB

–Full Scale

<–Full Scale

IN

Table I. Output Coding

CL

should be at least half the value of t

C

SC

(1000 s). From the time

specification). The duty cycle

Output Code

011 . . . 11

011 . . . 11

011 . . . 10

000 . . . 01

000 . . . 00

111 . . . 11

100 . . . 01

100 . . . 00

100 . . . 00

IN

CH

which occurs at the

) and LOW (t

AD676

CL

CLK

)

.