9946 3M, 9946 Datasheet - Page 15

9946

Manufacturer Part Number

9946

Description

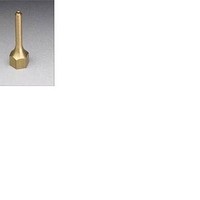

Soldering Tools .072 HOT MELT TIP SCOTCH WELD 3PC BAG

Manufacturer

3M

Type

Brass Extension Tipr

Datasheet

1.9946.pdf

(26 pages)

Specifications of 9946

Tip Size

0.072 mm

Product

Soldering Tips

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

021200-22040

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

994684-3

Manufacturer:

TE/AMP

Quantity:

30 000

Repair Procedures

13

Disconnect air and electrical power and make sure

applicator is at room temperature before servicing

3M™ Scotch-Weld™ Hot Melt Applicator PG II LT.

Failure to disconnect air and electrical power before

servicing may cause electrical shock or damage to the

applicator.

Procedure

C.

D.

G.

H.

A.

B.

E.

K.

F.

J.

I.

!

Caution

Handle Kit

Regulator Kit

Valve Kit

Hose Kit

Power Cord Kit

Switch Kit

Trigger Kit

Heat Shield Kit

Heater Kit

Thermostat/TCO Kit

Heat Block Kit

Part Kit

A. Handle Kit

Remove heat shield (see procedure H, page 16). With

the nozzle of the applicator pointing away from you,

remove the seven Phillips head cap screws in the

handle. These screws are located in the left hand side

of the handle grip, two in the pistol grip itself, two just

forward of the wire terminal and three to the rear of the

wire terminal. Without removing the wires from the

wire terminals, lift the handle up and to the front of the

applicator. This operation will allow for subsequent

repair steps.

To replace applicator handles, first follow “Handle

Disassembly Instructions.” Next remove the electrical

wiring from the terminal strip on the left handle,

replacing them to the same terminals on the

replacement. The right half of the handle is removed by

removing the four Phillips head cap screws. Next

remove the electrical wiring from the terminal strip and

re-assemble these to the replacement right half handle.

Lift the switch out of its slot in the handle and replace

it in the new handle. Replace the trigger and trigger pin

at this time. Using reverse procedure, reassemble the

right handle half, then the left. Be sure all the electrical

wires are in place and are not being pinched.

Handle Disassembly Instructions

© 3M 2006