9946 3M, 9946 Datasheet - Page 4

9946

Manufacturer Part Number

9946

Description

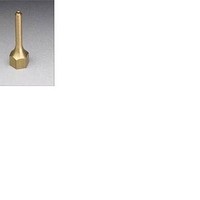

Soldering Tools .072 HOT MELT TIP SCOTCH WELD 3PC BAG

Manufacturer

3M

Type

Brass Extension Tipr

Datasheet

1.9946.pdf

(26 pages)

Specifications of 9946

Tip Size

0.072 mm

Product

Soldering Tips

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

021200-22040

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

994684-3

Manufacturer:

TE/AMP

Quantity:

30 000

The 3M™ Scotch-Weld™ Hot Melt Applicator PG II

LT is designed to be a simple, reliable tool for

dispensing 3M™ Scotch-Weld™ Hot Melt LM

Adhesive Sticks.

It is self-contained and hand held, designed for multi-

station or intermittent manual adhesive application.

The 3M Scotch-Weld Hot Melt Applicator PG II LT

uses electric heat to melt the adhesive, and air

pressure to deliver the adhesive. Adhesive

temperature is automatically maintained by a fixed

thermostat on the heat block. The system is further

protected by a thermal cutout (TCO), which acts as a

thermal fuse.

Please take time to properly fill out and return

your 3M Scotch-Weld Hot Melt Applicator PG II

LT Warranty Card.

© 3M 2006

Use 3M Scotch-Weld Hot Melt LM Adhesives only.

Use of other adhesives may damage the applicator or

result in hazardous conditions.

READ INSTRUCTIONS THOROUGHLY BEFORE OPERATING OR PERFORMING ANY

MAINTENANCE ON 3M™ SCOTCH-WELD™ HOT MELT APPLICATOR PG II LT.

!

Important

When trigger (1) is pulled, the variable regulator (2)

allows air pressure into rear of the Speedloader stick

feed (3). Air pushes the piston (4), which advances

adhesive stick through applicator. As adhesive

advances, it passes through hard plastic insulating

sleeve (5) which acts as thermal barrier to keep

molten adhesive and heat in forward portion of the

applicator. The rest of the applicator stays cool.

As adhesive advances into the heat block, it is melted

and liquefied. With pressure from the solid adhesive

sticks and the piston, the liquid adhesive is forced out

of the applicator through the nozzle tip (6). When the

trigger is released, air pressure is released from the

rear of the loading chamber. Pressure on the molten

adhesive in the front of the applicator is then also

relieved. Spring tension in the nozzle valve retracts

the valve, neatly cutting off the adhesive flow.

The delivery rate of molten adhesive for the 3M

Scotch-Weld Hot Melt Applicator PG II LT is

approximately six pounds per hour with 3M™

Scotch-Weld™ Hot Melt Adhesive 3762-LM utilizing

the standard tip 9921. Adhesive flow rates will vary

with the different 3M adhesives in the line and the

nozzle tip you choose.

General Information

2