TDA8947J/N3,112 NXP Semiconductors, TDA8947J/N3,112 Datasheet - Page 21

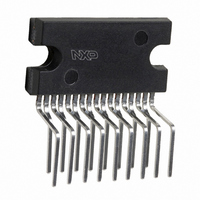

TDA8947J/N3,112

Manufacturer Part Number

TDA8947J/N3,112

Description

IC AMP AUDIO PWR 29W QUAD 17SIL

Manufacturer

NXP Semiconductors

Type

Class ABr

Datasheet

1.TDA8947JN3112.pdf

(24 pages)

Specifications of TDA8947J/N3,112

Output Type

4-Channel (Quad)

Package / Case

17-SIL (Bent and Staggered Leads)

Max Output Power X Channels @ Load

29W x 2 @ 8 Ohm; 14W x 4 @ 4 Ohm

Voltage - Supply

9 V ~ 26 V

Features

Depop, Mute, Short-Circuit and Thermal Protection, Standby

Mounting Type

Through Hole

Product

Class-AB

Output Power

29 W

Available Set Gain

32 dB

Thd Plus Noise

0.05 %

Operating Supply Voltage

18 V

Maximum Power Dissipation

69000 mW

Maximum Operating Temperature

+ 85 C

Mounting Style

Through Hole

Audio Load Resistance

8 Ohms

Input Signal Type

Single

Minimum Operating Temperature

- 40 C

Output Signal Type

Differential, Single

Supply Type

Single

Supply Voltage (max)

26 V

Supply Voltage (min)

9 V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

568-3458-5

935274472112

TDA8947J

935274472112

TDA8947J

Philips Semiconductors

16. Soldering

9397 750 14938

Product data sheet

16.1 Introduction to soldering through-hole mount packages

16.2 Soldering by dipping or by solder wave

16.3 Manual soldering

16.4 Package related soldering information

This text gives a brief insight to wave, dip and manual soldering. A more in-depth account

of soldering ICs can be found in our Data Handbook IC26; Integrated Circuit Packages

(document order number 9398 652 90011).

Wave soldering is the preferred method for mounting of through-hole mount IC packages

on a printed-circuit board.

Driven by legislation and environmental forces the worldwide use of lead-free solder

pastes is increasing. Typical dwell time of the leads in the wave ranges from

3 seconds to 4 seconds at 250 C or 265 C, depending on solder material applied, SnPb

or Pb-free respectively.

The total contact time of successive solder waves must not exceed 5 seconds.

The device may be mounted up to the seating plane, but the temperature of the plastic

body must not exceed the specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling may be necessary immediately

after soldering to keep the temperature within the permissible limit.

Apply the soldering iron (24 V or less) to the lead(s) of the package, either below the

seating plane or not more than 2 mm above it. If the temperature of the soldering iron bit is

less than 300 C it may remain in contact for up to 10 seconds. If the bit temperature is

between 300 C and 400 C, contact may be up to 5 seconds.

Table 12:

[1]

[2]

Package

CPGA, HCPGA

DBS, DIP, HDIP, RDBS, SDIP, SIL

PMFP

For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit

board.

For PMFP packages hot bar soldering or manual soldering is suitable.

[2]

Suitability of through-hole mount IC packages for dipping and wave soldering

methods

Rev. 02 — 16 June 2005

Soldering method

Dipping

-

suitable

-

© Koninklijke Philips Electronics N.V. 2005. All rights reserved.

4-channel audio amplifier

Wave

suitable

suitable

not suitable

TDA8947J

stg(max)

[1]

). If the

21 of 24