CYII5SC1300-EVAL Cypress Semiconductor Corp, CYII5SC1300-EVAL Datasheet - Page 38

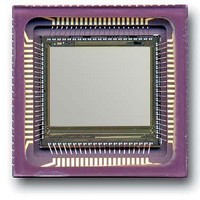

CYII5SC1300-EVAL

Manufacturer Part Number

CYII5SC1300-EVAL

Description

BOARD EVAL IMG SENS IBIS5-B-1300

Manufacturer

Cypress Semiconductor Corp

Specifications of CYII5SC1300-EVAL

Sensor Type

CMOS Imaging, Color (RGB)

Sensing Range

1.3 Megapixel

Interface

Parallel/Serial

Sensitivity

106 fps

Voltage - Supply

3 V ~ 4.5 V

Embedded

No

Utilized Ic / Part

IBIS5-B-1300

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

Document #: 38-05710 Rev. *A

Storage and Handling

Storage Conditions

Table 29.Storage Conditions

Handling and Soldering Conditions

Special care must be taken when soldering image sensors

with color filter arrays (RGB color filters) onto a circuit board

since color filters are sensitive to high temperatures.

Prolonged heating at elevated temperatures may result in

deterioration of the performance of the sensor. The following

recommendations are made to ensure that sensor perfor-

mance is not compromised during end-users' assembly

processes.

Board Assembly

Device placement onto boards must be done in accordance

with strict ESD controls for Class 0, JESD22 Human Body

Model, and Class A, JESD22 Machine Model devices.

Assembly operators must always wear all designated and

approved grounding equipment; grounded wrist straps at ESD

protected workstations are recommended including the use of

ionized blowers. All tools must be ESD protected.

Manual Soldering

When a soldering iron is used the following conditions must be

observed:

Use a soldering iron with temperature control at the tip. The

soldering iron tip temperature must not exceed 350°C.

The soldering period for each pin must be less than 5 seconds.

Reflow Soldering

Figure 42

for a reflow soldering system. If the temperature/time profile

Temperature

Description

shows the maximum recommended thermal profile

Minimum

–30

Figure 42. Reflow Soldering Temperature Profile

Maximum

+85

Units

°C

exceeds these recommendations damage to the image sensor

may occur. See

Precautions and Cleaning

Avoid spilling solder flux on the cover glass; bare glass and

particularly glass with antireflection filters may be adversely

affected by the flux. Avoid mechanical or particulate damage

to the cover glass.

It is recommended that isopropyl alcohol (IPA) be used as a

solvent for cleaning the image sensor glass lid. When using

other solvents, it must be confirmed beforehand whether or not

the solvent will dissolve the package and/or the glass lid.

RoHS (lead-free) Compliance

This paragraph reports the use of Hazardous chemical

substances as required by the RoHS Directive (excluding

packing material).

Table 30.The Chemical Substances and Information about

Any Intentional Content

Lead

Cadmium

Mercury

Hexavalent

chromium

PBB (Polybromi-

nated biphenyls)

PBDE (Polybro-

minated diphenyl

ethers)

Substance

Chemical

Figure 42

intentional

content?

Any

NO

NO

NO

NO

NO

NO

for more details.

CYII5FM1300AB

content, in which portion

If there is any intentional

IBIS5-B-1300

is it contained?

-

-

-

-

-

-

Page 38 of 42

[+] Feedback