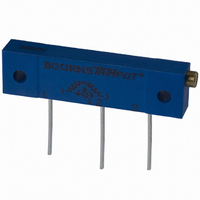

3059Y-1-500LF Bourns Inc., 3059Y-1-500LF Datasheet - Page 155

3059Y-1-500LF

Manufacturer Part Number

3059Y-1-500LF

Description

TRIMPOT 50 OHM 1.25"REC CER MT

Manufacturer

Bourns Inc.

Series

3059 - Sealedr

Specifications of 3059Y-1-500LF

Temperature Coefficient

±100ppm/°C

Resistance (ohms)

50

Termination Style

PC Pin

Power (watts)

1W

Tolerance

±10%

Number Of Turns

22

Adjustment Type

Side Adjustment

Resistive Material

Cermet

Mounting Type

Chassis Mount

Package / Case

Rectangular - 1.250" L x 0.190" W x 0.315" H (31.75mm x 4.83mm x 8.00mm)

Track Resistance

50ohm

No. Of Turns

22

Resistance Tolerance

± 10%

Power Rating

1W

Potentiometer Mounting

Through Hole

Resistance

50 Ohms

Operating Temperature Range

- 55 C to + 150 C

Element Type

Cermet

Dimensions

6.10 mm W x 31.75 mm L

Product

Trimmers

Taper

Linear

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Applications/Processing Guide – Standard and Lead Free

General Guidelines for Guarding Against Component Damage

To minimize temperature shock

To avoid heating components above their maximum rated

temperature

To limit time of exposure above rated temperature

To minimize temperature difference between top and bottom of

board

To reduce temperature shock on entering the moist environment

of the wash

To minimize temperature variations as component travels

through moisture

To minimize exposure to high-pressure water during board wash

Settability

Settability refers to the ease with which a trimmer can be set

accurately to the position that produces the desired circuit

condition.

Where the requirement is for obtaining a highly accurate setting

the preference is for cermet — because a small incremental

adjustment in a wirewound unit does not always produce the

expected change in output as the wiper moves off one turn of

wire and onto another.

Setting accuracy is better with a multiturn unit than with a

single-turn. This is especially true when the speed of setting is

also a requirement as on a production line (Figure 2).

• Pre-heat boards to maximum acceptable level

• Reduce time in solder

• Use lowest acceptable solder temperature

• Use maximum allowable conveyor speed

• Limit pre-heat temperature to maximum necessary

• Limit time in solder

• After solder operation, cool board to wash temperature

• Apply pre-heat to both top and bottom

• Use wash/rinse temperature as near component temperature

• Extend time between solder process and wash

• Cool board after solder operation, prior to entering wash

• Minimize number of wash/rinse and rinse/dry cycles

• Use heated air for air knives (to counter evaporative cooling

• Minimize difference between wash and rinse temperature

• Select trimmer models with pin styles that orient the rotor

before it enters wash

as possible

effect)

seal area away from exposure to the high-pressure water

stream

MV.

MV.

Stability

Stability refers to the ability of the trimmer to remain at the

desired setting. Environmental factors play an important role

here: stability may be affected by temperature exposure, thermal

shock/cycling, humidity, and mechanical shock or vibration.

This is not a matter of concern in most applications, since

Bourns® trimmers exhibit excellent stability under all specified

conditions. Stability is most often a concern when cermet

trimmers are used in low current “dry” circuits (50 uA and

below). Under these conditions the contact resistance may vary,

making the wiper appear unstable. This is most noticeable in

some rheostat applications. This can be avoided by using a

wirewound unit, or choosing a cermet trimmer that has been

designed for dry-circuit applications. Bourns applications

engineers can assist you on this and other questions.

Accessability

When selecting a trimmer and determining its placement on the

board, keep in mind the people who will have to use it. Bourns®

trimmers are available in a wide variety of sizes, shapes,

configurations, and placement of adjustment screws. You will

usually find a unit on which the access for adjustment will be

convenient for the user.

Keep in mind the different requirements for accessibility

depending on whether adjustment will be done on the assembly

line or in the field; with the board uncovered, in a housing or

cabinet, or on an extender. Also consider whether production-

line adjustment will be done manually or by robotics. A Bourns

applications engineer can advise on special high-speed automatic

adjustment features.

400

300

200

500

400

0

SINGLE-TURN SETTABILITY (3386)

1.7

LESS EXPERIENCED

3.4

EXPERIENCED

TECHNICIAN

TECHNICIAN

When accurate setting is required, a multiturn trimmer

SEC.

5.1

can generally be set faster than a single-turn.

6.8

8.5

10.2

Figure 2.

M.V.

M.V.

400

400

0

MULTITURN SETTABILITY (3299)

1.7

LESS EXPERIENCED

3.4

EXPERIENCED

TECHNICIAN

TECHNICIAN

SEC.

5.1

6.8

8.5

153

10.2