TMC SIXPACK 2 TRINAMIC, TMC SIXPACK 2 Datasheet - Page 7

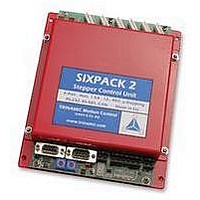

TMC SIXPACK 2

Manufacturer Part Number

TMC SIXPACK 2

Description

CONTROLLER, STEPPER MOTOR, AMPLIF

Manufacturer

TRINAMIC

Datasheet

1.TMC_SIXPACK_2.pdf

(48 pages)

Specifications of TMC SIXPACK 2

Supply Voltage Range

15Vdc To 48Vdc

No. Of Phases

Two

Output Current

1.4A

Approval Bodies

CE

Current Limit Max

1.4A

Current Limit Min

300mA

External Depth

35mm

External Length / Height

180mm

Svhc

No SVHC (15-Dec-2010)

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

SIXpack 2 – manual (V1.01 / May 5

3 System Start Up

3.1 System Start Up / Notes

When the SIXpack 2 is supplied with power it runs an internal initialization and a self-test of the internal

processor-system starts. If executed successfully a “0“ appears in the LED-display after a second. The

SIXpack 2 is operational now and can receive user commands.

Defective motor drivers can not be detected by the self test. Should the motor turn on and off during

operation, a constant high motor current or insufficient cooling of the drivers could be the problem. The

motor driver chip turns itself off for a short time when overheated. This condition should not occur in a

normal operation condition. If the SIXpack 2 reports a board temperature above or near 85°C, a forced

air cooling or other means to reduce heat dissipation, like reduction of stand by motor current is

proposed to ensure a long product life time.

When an application requires detection of temporarily interrupted power supply of the SIXpack 2, this

can be done for example by signaling via external TTLOUT1 by programming it to a negative level. It will

return to a high level after a reset. The RS 232-interface usually receives a 0-byte after hardware reset.

3.2 Selecting Motors

When selecting motors, consider stepper motors with the lowest inductance possible, i.e. low coil

resistance, to obtain smoothest movements and the maximum possible RPM. On the other hand low coil

resistance increases the required motor current. Therefore you should choose the motor with the lowest

inductance possible which delivers the required torque at a coil current of approx. 1000 to 1400 mA.

Highest possible operating voltage of the SIXpack 2 results in high RPM also. With higher coil resistance

or a too low operating voltage the duty factor of the chopper drivers increases. When exceeding 50% a

chirping noise can occur in the coils.

3.3 Length of Wires

motor wires:

RS 232:

CAN, RS485:

3.4 Grounding

For a good ESD protection the electronics must be connected effectively with ground. Therefore two

holes are provided on the PCB with ground contacts.

If the electronics is delivered without housing, these two screws must be connected to ground.

If the electronics are built-in in the housing the protection tape must be taken away of the two fixing

drilled holes on the back side. The electronics must now be grounded via these two blank areas.

3.5 Improvement of the EMC-Conduction

To improve the cable-bound conducted emission, a ferrite-clip should be clipped over the supply circuit.

3.6 Further Information:

For further information please view our homepage (www.trinamic.com). You will find help under

“frequently asked questions”. You also have the possibility to send us an e-mail via a contact sheet

located on the same site.

typically < 3m (use twisted pair wire)

typically < 3m

can be > 30m

th

, 2006) 7