QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 23

QDE-825D

Manufacturer Part Number

QDE-825D

Description

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

EZ-SCREEN

Instruction Manual

Before installing the EZ-SCREEN System, read Section 1.2

and Section 3 of this manual in their entirety. The System’s

ability to perform its safety guarding function depends upon

the appropriateness of the application and upon its proper

mechanical and electrical installation and interfacing to the

guarded machine. If all mounting, installation, interfacing, and

checkout procedures are not followed properly, the System

cannot provide the protection for which it was designed.

Installation must be performed by a Qualified Person, as defined

in Section 4.1. See Warning below.

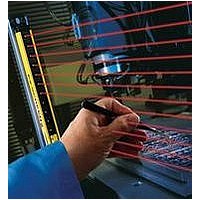

The two factors that influence the layout of the EZ-SCREEN’s

mechanical installation the most are separation distance and

hard guarding. Other considerations include emitter and receiver

orientation, adjacent reflective surfaces, use of corner mirrors,

and installation of multiple EZ-SCREEN emitter/receiver pairs.

3. Installation and Alignment

3.1 Mechanical Installation Considerations

The user is responsible for satisfying all local, state, and

national codes and regulations relating to the installation and

use of this control system in any particular application. Take

extreme care to meet all legal requirements and follow all technical

installation and maintenance instructions contained in this manual.

The user has the sole responsibility to ensure that the

EZ-SCREEN System is installed and interfaced to the guarded

machine by Qualified Persons in accordance with this manual

and with applicable safety regulations.

Read Section 1.2 and all of Section 3 of this manual carefully before

installing the system. Failure to follow these instructions could

result in serious bodily injury or death.

The emitter and receiver must be positioned such that the

hazard can not be accessed by reaching over, under, around

or through the sensing field. Additional guarding may be required;

see Separation Distance, Section 3.1.1, and Pass-Through Hazards,

Section 3.1.2, and Supplemental Safeguarding, Section 3.1.4.

Banner Engineering Corp.

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

WARNING . . .

Before Installing the System

WARNING . . .

Carefully

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

Read this Section Carefully

Position Components

Minimum Separation Distance (Ds) is the minimum distance

required between the defined area and the closest reachable

hazard point. Separation distance is calculated so that when an

object or a person is detected (by blocking a sensing beam),

the EZ-SCREEN will send a stop signal to the machine, causing

it to stop by the time the person can reach any machine hazard

point.

Calculation of separation distance takes into account several

factors, including a calculated human speed, the total system

stopping time (which itself has several components), and the

depth penetration factor. After the separation distance (Ds)

is determined, record the calculated distance on the Daily

Checkout Card.

Figure 3-1. Separation distance and hard guarding

Guarding

3.1.1 Separation Distance (Safety Distance)

Banner EZ-SCREEN emitters and receivers must be mounted at

a distance from the nearest hazard such that an individual cannot

reach the hazard before cessation of hazardous motion or situation.

Failure to establish and maintain the minimum separation

distance could result in serious bodily injury or death.

Hard

WARNING . . .

Hard Guarding

EZ-SCREEN

EZ-SCREEN

Reset Switch

Installation and Alignment

Ds

Robot

Proper Separation Distance

Turn-

table

Nearest Hazard Point

Overview

P/N 112852 rev. F

P/N 133487

21

21