QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 36

QDE-825D

Manufacturer Part Number

QDE-825D

Description

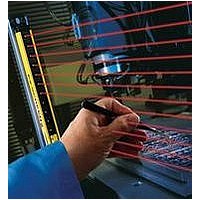

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

34

34

If all Zone indicators turn Green or fail to follow the position

of the test piece while it is within the defined area, the

installation has failed the trip test. Check for correct sensor

orientation, reflective surfaces and unguarded areas created

due to the use of Blanking. Do not continue until the situation is

corrected.

When the test piece is removed from the defined area, in Trip

Output Operation, the Status indicator must turn ON Green (or

flash Green, if Reduced Resolution is enabled). In Latch Output

Operation, the Status indicator will remain Red until a manual

reset is performed (the Yellow Reset indicator will be flashing).

If mirrors are used in the application: Test the defined area

on each leg of the sensing path (e.g. emitter to mirror, between

mirror and receiver, see Figure 3-15).

If the EZ-SCREEN System passes all three checks during the

trip test, go on to Section 3.5.

If the EZ-SCREEN System does not respond properly to the

trip test, do not attempt to use the System.

If this occurs, the EZ-SCREEN cannot be relied on to stop

dangerous machine motion when a person or object enters the

defined area.

Serious bodily injury or death could result.

P/N 133487

P/N 112852 rev. F

Installation and Alignment

Overview

WARNING . . .

Problem

If Trip Test Indicates a

Permanent Hookup

Make the electrical connections as described in Sections 3.5.1 to

3.5.4 as required by each individual application.

Lockout/tagout procedures may be required (refer to OSHA

1910.147, ANSI Z244-1, or the appropriate standard for

controlling hazardous energy). Follow relevant electrical

standards and wiring codes, such as the NEC, NFPA79 or IEC

60204-1. See the warning in Section 3.3.

Supply power and the external reset switch should already be

connected. The EZ-SCREEN must also have been aligned and

passed the Initial Checkout, as described in Section 3.4.

The final connections to be made are:

• OSSD outputs

• FSD interfacing

• MPCE/EDM connections

• Optional remote Test

3.5 Electrical Interface to the Guarded Machine

Both of the OSSD (Output Signal Switching Device) outputs

must be connected to the machine control so that the machine’s

safety-related control system interrupts the circuit to the machine

primary control element(s), resulting in a non-hazardous condition.

Never wire an intermediate device(s) (e.g., PLC, PES, PC)

that can fail in such a manner that there is the loss of the

safety stop command, OR in such a manner that the safety

function can be suspended, overridden, or defeated, unless

accomplished with the same or greater degree of safety.

To ensure proper operation, the EZ-SCREEN OSSD output

parameters and machine input parameters must be considered

when interfacing the EZ-SCREEN solid-state OSSD outputs to

machine inputs.

Machine control circuitry must be designed so that the maximum

load resistance value is not exceeded and that the maximum

specified OSSD OFF-state voltage does not result in an

ON condition.

Failure to properly interface the OSSD outputs to the guarded

machine could result in serious bodily injury or death.

Always disconnect all power from the EZ-SCREEN System

and the guarded machine before making any connections or

replacing any component. Use extreme caution to avoid electrical

shock at all times.

WARNING . . .

WARNING . . .

WARNING . . .

Banner Engineering Corp.

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

Shock Hazard

Interfacing of Both OSSDs

OSSD Interfacing

Instruction Manual

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

EZ-SCREEN