QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 63

QDE-825D

Manufacturer Part Number

QDE-825D

Description

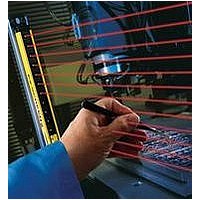

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

EZ-SCREEN

Instruction Manual

Setting cascaded sensors for scan code, trip or latch output,

external device monitoring (EDM), reduced resolution, fixed

blanking and inverted display is identical to the procedure for

non-cascadeable emitters and receivers (see Section 4).

Scan codes for each emitter and receiver pair must match.

However, for cascaded installations, scan codes must alternate

on adjacent systems as described in Section 3.1.8 and Figure

3-8. See warning below.

While the scan code, reduced resolution, fixed blanking, and

inverted display settings are independent for each cascaded

sensor pair, the trip/latch mode and EDM settings must be

determined by the first receiver in the cascade (closest to the

machine interface), which controls the OSSD outputs. All other

receivers in the cascade must be set for trip mode and

2-channel EDM (factory default settings).

The settings on the first receiver then determine trip or latch

mode and 1- or 2-channel EDM/aux. output, and this is the only

receiver that requires a reset following a latch condition.

One or more areas within any cascaded EZ-SCREEN sensor

pair can be blanked out, just as with other EZ-SCREEN light

screens. Each sensor pair within a cascade must be

programmed separately, if required. See Section 3.4.3 for

more information and programming procedure.

Each cascaded system must be configured, before it can be run

in a production environment.

Before configuration, install all emitters and receivers per

Sections 3 and 7. The last receiver must be terminated

either with a terminator plug or by connecting two closed

mechanical contacts (see Sections 7.8 and 7.9).

7.6 Cascaded Sensor Configuration Settings

7.6.1 Fixed Blanking

7.7 Configuration for Cascaded Operation

Banner Engineering Corp.

Banner Engineering Corp.

In situations where multiple systems are mounted closely

together, or where a secondary emitter is in view (within ±5°),

within range of an adjacent receiver; the adjacent systems must be

configured for different Scan Codes (i.e., one system set for Scan

Code 1 and the other for Scan Code 2).

If not, a receiver may synchronize to the signal from the wrong

emitter, reducing the safety function of the light screen.

This situation will be discovered by performing the trip test

(see Section 3.4.3).

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

WARNING . . .

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

Scan Code

Perform the following procedure on the first receiver only in

the cascade (closest to the machine interface).

1. From either normal operation or a power OFF condition, set

2. Set the third and fourth DIP switches (the second T/L and RR)

3. The receiver should be in a lockout condition or power OFF.

4. If power is OFF: Apply power

5. Coming out of lockout or during startup, the DIP switch

• F irst receiver display shows

• L ast cascaded receiver display shows

• O ther receivers display “1C” ON steady

• All receiver Zone indicators OFF

• All receiver Yellow reset indicators OFF

• All receiver Status indicators solid red

6. To enable and exit Cascade Teach Mode, reconfigure DIP

7. Perform a valid reset sequence (see Step 4), or cycle power.

Figure 7-7. DIP switch configuration to enable cascade installation

1. Install cascade system per Sections 3

With Power ON:

2. Set T/L and RR switches as shown on

3. Press the Reset button or cycle power.

4. Reconfigure DIP switches for normal

5. Press the Reset button or cycle power.

NO TE: If the EDM wiring does not match

the second and fifth DIP switches (RR and T/L) both to the

left (RR and T position).

both to the right (L and OFF position); see Figure 7-7.

Lockout condition: Perform a valid reset sequence (close

the reset switch for 0.25 to 2 seconds, then reopen).

configuration will be recognized as Cascaded Teach Mode,

indicated by the following:

switches for normal operation.

and 7 of this manual.

first receiver only (do not change

SC2/SC1 or E1/E2 switch positions).

operation.

Terminator connected: “1C” ON steady

E-stop w/closed contacts: “1CE” ON steady

E-stop w/open contacts: “1CE” flashing

the switch position shown (E2), an

EDM error occurs and fixed blanking

or cascade configuration will not be

allowed.

No E-stop connected: “4C,” “3C,” or “2C” ON steady

E-stop w/closed contacts: “4CE,” “3CE,” or “2CE” ON

E-stop w/open contacts: “4CE,” “3CE” or “2CE” flashing

steady

Cascadeable EZ-SCREEN

Overview

P/N 112852 rev. F

P/N 133487

61

61