QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 5

QDE-825D

Manufacturer Part Number

QDE-825D

Description

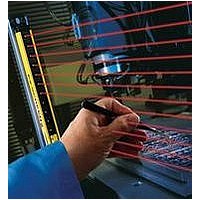

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

EZ-SCREEN

Instruction Manual

The Banner EZ-SCREEN models described by this manual

feature several standard selectable functions:

• Reduced Resolution (Floating Blanking),

• Trip or Latch Output,

• External Device Monitoring (EDM),

• Auxiliary Output,

• Scan Code setting,

• Fixed Blanking,

• Inverted Display, and

• Cascading (available on SLSC.. models).

These functions are configured within the sensors, behind the

access cover on the front of each sensor and in the sensor

wiring configuration; see Sections 3 and 4.2 for more information

and configuration DIP switches.

The resolution and the maximum range can be determined by

the model number on the emitter and receiver. See Section 2 for

a list of model numbers.

The setting for Trip or Latch Output also determines whether the

System will enter RUN mode automatically or if it will require a

manual reset first (see Sections 1.4.8 and 4.2). If the System is

set for Trip Output, other measures must be taken to prevent a

pass-through hazard; see Section 3.1.2 and the warning below

for more information.

If Trip Output is selected, the OSSD outputs will turn ON after

power is applied, and the receiver passes its internal self-test/

synchronization and recognizes that all beams are clear. The

Trip Output will also automatically reset after all beams are

cleared. If Latch Output is selected, the EZ-SCREEN requires

a manual reset for the OSSD outputs to turn ON, after power is

applied and all beams are clear (see Section 4.5).

1.4 Operating Features

1.4.1 Selectable Trip/Latch Output

Application of power to the EZ-SCREEN components, the

clearing of the defined area, or the reset of a Latch condition

MUST NOT initiate dangerous machine motion. Machine control

circuitry must be designed so that one or more initiation devices

must be engaged (i.e., a conscious act) to start the machine – in

addition to the EZ-SCREEN going into RUN mode. Failure to follow

these instructions could result in serious bodily injury or death.

Banner Engineering Corp.

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

WARNING . . .

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

Use of Trip/Latch Output

An EZ-SCREEN emitter with an 8-pin connector can be

connected to its own power supply or to the receiver cable

color-for-color (see Figures 3-19 and 3-20). The color-for-

color hookup allows the emitter and receiver positions to be

interchanged without rewiring.

NOTE: An EZ-SCREEN emitter with 5-pin connector and Test

This feature allows the EZ-SCREEN System to monitor the

status of external devices, such as MPCEs. The choices are

1- or 2-channel monitoring, or no monitoring. EDM is used when

the EZ-SCREEN OSSD outputs directly control the MPCEs or

other external devices; see Sections 3.5.3 and 4.2 for more

information.

Auxiliary (Aux.) Output

An aux. output function is available when the receiver is

configured for 1-channel EDM (for receivers with date code

0834 or newer). This current sourcing (PNP) solid-state output

(75 mA max.) is used for control functions that are not safety-

related. A typical use is to signal the state of the OSSDs to a

programmable logic controller (PLC). The aux. output follows

the state of the OSSDs. Pin 2 (orange/black) supplies the

connection; see Section 3.5.5 and Figure 3-23.

On 5-pin EZ-SCREEN emitter models (model numbers SLSE..-..

Q5; see Tables 2.1 and 2.2), a Test function is provided. A pair

of wires is connected from the emitter (see Section 3.5.6) to an

external switch, typically a normally open contact, held closed.

Opening a switch connected between these two terminals “turns

off” the emitter, simulating an interruption of one or more light

beams. This remote Test input may be useful for EZ-SCREEN

System setup and to verify machine control circuit operation.

The emitter and receiver may be configured to one of two

Scan Code positions (1 or 2). Scan codes enable a receiver

to recognize beams only from an emitter with the same Scan

Code setting. This helps minimize the effects of crosstalk

between multiple emitter/receiver pairs, and allows multiple

pairs to operate in close proximity in certain situations. See

Sections 3.1.5 and 3.1.8 for proper mounting configurations.

The Scan Code is set using the selection switch in each

sensor’s configuration port; see Section 4.2 for more

information. Both the emitter and its corresponding receiver

must be set to the identical setting.

1.4.2 Emitter QD and Hookup Options

1.4.3 External Device Monitoring (EDM)

1.4.4 Remote Test Input

1.4.5 Scan Code Configuration

function (see Section 1.4.4) is not capable of the color-

for-color hookup.

Overview

Overview

P/N 112852 rev. F

P/N 133487

3

3