QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 33

QDE-825D

Manufacturer Part Number

QDE-825D

Description

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

EZ-SCREEN

Instruction Manual

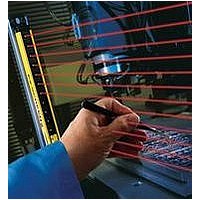

4. Optical Alignment

Optical Alignment Procedure with Mirrors

EZ-SCREEN sensors may be used with one or more corner

mirrors for guarding more than one side of an area. The

MSM... and SSM-... rear-surface glass mirrors are rated at 85%

efficiency. Thus, excess gain and sensing range are reduced

when using mirrors; see Section 3.1.7.

Banner Engineering Corp.

Banner Engineering Corp.

CAUTION: Ensure that no individuals are exposed to any

Verify sensor mounting per Section 3.2.

Verify Optimal Alignment (Rotational Adjustment with power

ON)

a. Ensure the emitter and receiver are pointed squarely

b. If Channel #1 beam is not aligned, the Status and

c. If the Green Status and Yellow Reset indicators are

d. To optimize alignment, note the position where the Red

e. If, at any time, the Red Status indicator begins to flash

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

NOTE: At power-up, all indicators are tested (flash), then

ON, go to step “d”. If not, rotate each sensor (one at a

time) left and right until the Green Status indicator comes

ON. As the sensor rotates out of alignment, the Red Status

indicator will come ON steady. As more beams are made,

the Zone indicators will turn from Red to Green and the

number of blocked beams displayed will decrease.

NOTE: If the Emitter’s Test input is open, the 7-segment

For situations where alignment is difficult, a LAT-1-SS

Laser Alignment Tool can be used to assist or confirm

alignment by providing a visible red dot along the sensor’s

optical axis (see Figure 3-13).

at each other. A straight edge (e.g., a level) can determine

the direction the sensor is facing (see Figure 3-11). The

sensor face must be perpendicular to the optical axis.

Zone 1 indicators are Red and the Diagnostic Display

indicates “CH1”. Zone indicators 2-8 will be OFF.

Status indicator comes ON when the sensor is rotated both

left and right. Center the sensor between the two positions,

and tighten the end cap mounting screws, making sure

the positioning does not drift as the screws are tightened.

Repeat for second sensor.

steadily, the System has entered a Lockout condition. See

Section 5.1.1 for further information.

the Scan Code is displayed.

display will indicate the total number of beams

(minus one) in the System and all Zone indicators

will be Red (except for 10-beam systems, where the

Zone 1 indicator will be Green).

hazard if the EZ-SCREEN receiver turns ON the

OSSD outputs when the System becomes aligned.

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

Figure 3-11. Optimum optical alignment

In addition to the standard optical alignment procedure, verify

(see Figure 3-12):

• T hat the emitter, receiver, and all mirrors are level and plumb,

• T he middle of the defined area and the center point of the

During any adjustments, allow only one individual to adjust any

one item at any one time.

NOTE: A LAT-1-SS Laser Alignment Tool is very helpful by

a.

b.

c.

d.

e.

mirrors are approximately the same distance from a common

reference point, such as the same height above a level floor.

Ensure that there are equal amounts of mirror surface above

and below the defined area such that the optical beams are

not passing below or above the mirror.

Straight Edge

providing a visible red dot along the optical axis. See

Figure 3-13 and Banner Safety Applications Note SA104

(P/N 57477) for further information.

Installation and Alignment

Straight Edge

C1 or C2

ON Red

# Beams

ON Red

Flashing

Blocked

ON

Green

Green

Dash

All

OFF

OFF

Overview

CH1

Code

Error

OFF

All

or

Yellow

OFF

Yellow Red

P/N 112852 rev. F

OFF

OFF

Flashing

Red

P/N 133487

Green

31

31