QDE-825D BANNER ENGINEERING, QDE-825D Datasheet - Page 4

QDE-825D

Manufacturer Part Number

QDE-825D

Description

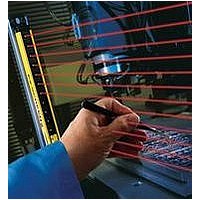

Safety Light Curtain

Manufacturer

BANNER ENGINEERING

Datasheet

1.QDE-815D.pdf

(74 pages)

Specifications of QDE-825D

Light Curtain Type

Safety

Accessory Type

Machine Interface Cable

For Use With

EZ-Screen Safety Light Screen

2

2

The Banner EZ-SCREEN is intended for point-of-operation

machine guarding applications and other safeguarding

applications. It is the user’s responsibility to verify whether the

safeguarding is appropriate for the application and is installed,

as instructed by this manual, by a Qualified Person.

Before installing the EZ-SCREEN, read this manual in its

entirety, paying particular attention to this section and all of

Section 3. The EZ-SCREEN’s ability to perform its safeguarding

function depends upon the appropriateness of the application

and upon its proper mechanical and electrical installation

and interfacing to the guarded machine. If all mounting,

installation, interfacing, and checkout procedures are not

followed properly, the EZ-SCREEN cannot provide the

protection for which it was designed.

EZ-SCREEN is typically used, but is not limited to, the

following applications:

• Small assembly equipment

• Molding and power presses

• Automated production equipment

• Robotic work cells

• Assembly and packaging machines

• Lean manufacturing systems

EZ-SCREEN may NOT be used with the following machinery

or unsuitable applications:

• A ny machine that cannot be stopped immediately after a stop

• A ny machine with inadequate or inconsistent machine

• A ny machine that ejects materials or component parts through

• I n any environment that is likely to adversely affect

• A s a tripping device to initiate or reinitiate machine motion

If an EZ-SCREEN is installed for use as a perimeter guard

(i.e., where a pass-through hazard may exist), the dangerous

machine motion can be initiated by normal means only

after the safeguarded area is clear of individuals and the

EZ-SCREEN has been manually reset. See Section 3.1.2.

P/N 133487

P/N 112852 rev. F

signal is issued, such as single-stroke (or “full-revolution”)

clutched machinery.

response time and stopping performance.

the defined area.

(PSDI applications), unless the machine and its control system

fully comply with the relevant standard or regulation (see

OSHA 29CFR1910.217, ANSI/NFPA 79, ANSI B11, ANSI/

RIA R15.06, ISO 12100, IEC 60204-1, IEC 61496, or other

appropriate standard).

1.2 Applications and Limitations

photoelectric sensing efficiency. For example, corrosive

chemicals or fluids or unusually severe levels of smoke or

dust, if not controlled, may degrade sensing efficiency.

Overview

Overview

Redundancy requires that EZ-SCREEN System circuit

components be “backed up” to the extent that, if the failure of

a single component will prevent effective machine stopping

action when needed, that component must have a redundant

counterpart which will perform the same function. The

EZ-SCREEN is designed with redundant microprocessors.

Redundancy must be maintained for as long as the EZ-SCREEN

is in operation. Because a redundant system is no longer

redundant after a component has failed, EZ-SCREEN is

designed to monitor itself continuously. A component failure

detected by or within the self-checking system causes a

“stop” signal to be sent to the guarded machine and puts the

EZ-SCREEN into a Lockout condition.

Recovery from this type of Lockout condition requires:

• r eplacement of the failed component (to restore redundancy)

• the appropriate reset procedure (see Section 1.4.8).

The Diagnostic Display is used to diagnose causes of a Lockout

condition (see Section 5.1).

1.3 Control Reliability: Redundancy and Self-Checking

The user is responsible for satisfying all local, state, and national

laws, rules, codes, or regulations relating to the installation and

use of this control system in any particular application. Take

extreme care to meet all legal requirements and follow all installation

and maintenance instructions contained in this manual.

The user has the sole responsibility to ensure that the

EZ-SCREEN is installed and interfaced to the guarded machine

by Qualified Persons in accordance with this manual and

applicable safety regulations.

Carefully read this manual in its entirety, paying particular attention to

Section 1.2 and all of Section 3, before installing the System. Failure

to follow these instructions could result in serious bodily injury

or death.

Banner EZ-SCREEN is for use only on machinery that can be

stopped immediately after a stop signal is issued at any point in

the machine’s stroke or cycle, such as part-revolution clutched

machines. Under no circumstances may EZ-SCREEN be used

on full-revolution clutched machinery or in unsuitable applications

as those listed at left. If there is any doubt about whether or

not your machinery is compatible with EZ-SCREEN, contact

Banner’s Application Engineers at the factory.

and

WARNING . . .

Before Installing the System

WARNING . . .

Appropriate Applications

Banner Engineering Corp.

Banner Engineering Corp.

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

Read this Section Carefully

Install EZ-SCREEN Only on

Instruction Manual

•

•

Minneapolis, U.S.A.

Minneapolis, U.S.A.

EZ-SCREEN