MA180023 Microchip Technology, MA180023 Datasheet - Page 381

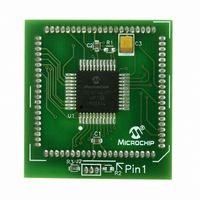

MA180023

Manufacturer Part Number

MA180023

Description

MODULE PLUG-IN PIC18F46J11 PIM

Manufacturer

Microchip Technology

Series

PIC®r

Datasheet

1.MA180023.pdf

(528 pages)

Specifications of MA180023

Accessory Type

Plug-In Module (PIM) - PIC18F46J11

Tool / Board Applications

General Purpose MCU, MPU, DSP, DSC

Mcu Supported Families

PIC18

Supported Devices

Stand-alone Or W/ HPC(DM183022) Or PIC18(DM183032)

Silicon Manufacturer

Microchip

Core Architecture

PIC

Core Sub-architecture

PIC18

Silicon Core Number

PIC18F

Silicon Family Name

PIC18FxxJxx

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With/related Products

HPC Explorer Board (DM183022) or PIC18 Explorer Board (DM183032)

For Use With

DM183032 - BOARD EXPLORER PICDEM PIC18DM183022 - BOARD DEMO PIC18FXX22 64/80TQFP

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

MA180023

Manufacturer:

Microchip Technology

Quantity:

135

- Current page: 381 of 528

- Download datasheet (8Mb)

24.4

There are two separate methods of measuring capaci-

tance with the CTMU. The first is the absolute method,

in which the actual capacitance value is desired. The

second is the relative method, in which the actual

capacitance is not needed, rather an indication of a

change in capacitance is required.

24.4.1

For absolute capacitance measurements, both the

current and capacitance calibration steps found in

Section 24.3 “Calibrating the CTMU Module”

should be followed. Capacitance measurements are

then performed using the following steps:

1.

2.

3.

4.

5.

6.

7.

8.

© 2009 Microchip Technology Inc.

Initialize the A/D Converter.

Initialize the CTMU.

Set EDG1STAT.

Wait for a fixed delay, T.

Clear EDG1STAT.

Perform an A/D conversion.

Calculate the total capacitance, C

where I is known from the current source

measurement step (see Section 24.3.1 “Current

Source Calibration”), T is a fixed delay and V is

measured by performing an A/D conversion.

Subtract the stray and A/D capacitance

(C

Calibration”) from C

measured capacitance.

OFFSET

Measuring Capacitance with the

CTMU

ABSOLUTE CAPACITANCE

MEASUREMENT

from Section 24.3.2 “Capacitance

TOTAL

to determine the

TOTAL

= (I * T)/V,

PIC18F46J11 FAMILY

24.4.2

An application may not require precise capacitance

measurements. For example, when detecting a valid

press of a capacitance-based switch, detecting a rela-

tive change of capacitance is of interest. In this type of

application, when the switch is open (or not touched),

the total capacitance is the capacitance of the combina-

tion of the board traces, the A/D Converter, etc. A larger

voltage will be measured by the A/D Converter. When

the switch is closed (or is touched), the total

capacitance is larger due to the addition of the

capacitance of the human body to the above listed

capacitances, and a smaller voltage will be measured

by the A/D Converter.

Detecting capacitance changes is easily accomplished

with the CTMU using these steps:

1.

2.

3.

4.

5.

The voltage measured by performing the A/D conver-

sion is an indication of the relative capacitance. Note

that in this case, no calibration of the current source or

circuit capacitance measurement is needed. See

Example 24-4 for a sample software routine for a

capacitive touch switch.

Initialize the A/D Converter and the CTMU.

Set EDG1STAT.

Wait for a fixed delay.

Clear EDG1STAT.

Perform an A/D conversion.

RELATIVE CHARGE

MEASUREMENT

DS39932C-page 381

Related parts for MA180023

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet: