MA180025 Microchip Technology, MA180025 Datasheet - Page 312

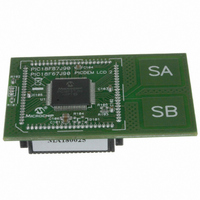

MA180025

Manufacturer Part Number

MA180025

Description

MODULE PLUG-IN PIC18F87J90 PIM

Manufacturer

Microchip Technology

Series

PIC®r

Specifications of MA180025

Accessory Type

Plug-In Module (PIM) - PIC18F87J90

Product

Microcontroller Modules

Silicon Manufacturer

Microchip

Core Architecture

PIC

Core Sub-architecture

PIC18

Silicon Core Number

PIC18F

Silicon Family Name

PIC18FxxJxx

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With/related Products

PICDEM LCD 2 Demonstration Board (DM163030)

For Use With

DM163030 - KIT DEV PICDEM LCD2

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

MA180025

Manufacturer:

Microchip Technology

Quantity:

135

Company:

Part Number:

MA180025

Manufacturer:

MICROCHIP

Quantity:

12 000

- Current page: 312 of 450

- Download datasheet (4Mb)

PIC18F87J90 FAMILY

The CTMU current source may be trimmed with the

trim bits in CTMUICON using an iterative process to get

an exact desired current. Alternatively, the nominal

value without adjustment may be used; it may be

stored by the software for use in all subsequent

capacitive or time measurements.

To calculate the value for R

must be chosen and then the resistance can be

calculated. For example, if the A/D Converter reference

voltage is 3.3V, use 70% of full scale or 2.31V as the

desired approximate voltage to be read by the A/D

Converter. If the range of the CTMU current source is

selected to be 0.55 A, the resistor value needed is cal-

culated as R

Similarly, if the current source is chosen to be 5.5 A,

R

source is set to 55 A.

FIGURE 24-2:

DS39933D-page 312

CAL

would be 420,000Ω, and 42,000Ω if the current

ANx

R

CAL

CAL

= 2.31V/0.55 A for a value of 4.2 MΩ.

CTMU CURRENT SOURCE

CALIBRATION CIRCUIT

Current Source

MUX

PIC18F87J90

CAL

A/D Converter

, the nominal current

A/D

A/D

Trigger

CTMU

manually triggers the A/D Converter. This is done to

demonstrate the entire stepwise process. It is also

possible to automatically trigger the conversion by

setting the CTMU’s CTTRIG bit (CTMUCONH<0>).

A value of 70% of full-scale voltage is chosen to make

sure that the A/D Converter is in a range that is well

above the noise floor. Keep in mind that if an exact cur-

rent is chosen to incorporate the trimming bits from

CTMUICON, the resistor value of R

adjusted accordingly. R

allow for available resistor values. R

the highest precision available, keeping in mind the

amount of precision needed for the circuit that the

CTMU will be used to measure. A recommended

minimum would be 0.1% tolerance.

The following examples show one typical method for

performing a CTMU current calibration. Example 24-1

demonstrates how to initialize the A/D Converter and the

CTMU; this routine is typical for applications using both

modules. Example 24-2 demonstrates one method for

the actual calibration routine. Note that this method

2010 Microchip Technology Inc.

CAL

may be also adjusted to

CAL

CAL

may need to be

should be of

Related parts for MA180025

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet: