MA180025 Microchip Technology, MA180025 Datasheet - Page 32

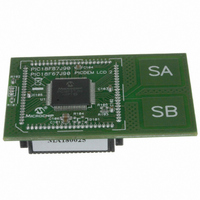

MA180025

Manufacturer Part Number

MA180025

Description

MODULE PLUG-IN PIC18F87J90 PIM

Manufacturer

Microchip Technology

Series

PIC®r

Specifications of MA180025

Accessory Type

Plug-In Module (PIM) - PIC18F87J90

Product

Microcontroller Modules

Silicon Manufacturer

Microchip

Core Architecture

PIC

Core Sub-architecture

PIC18

Silicon Core Number

PIC18F

Silicon Family Name

PIC18FxxJxx

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With/related Products

PICDEM LCD 2 Demonstration Board (DM163030)

For Use With

DM163030 - KIT DEV PICDEM LCD2

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

MA180025

Manufacturer:

Microchip Technology

Quantity:

135

Company:

Part Number:

MA180025

Manufacturer:

MICROCHIP

Quantity:

12 000

- Current page: 32 of 450

- Download datasheet (4Mb)

PIC18F87J90 FAMILY

2.2

2.2.1

The use of decoupling capacitors on every pair of

power supply pins, such as V

AV

Consider the following criteria when using decoupling

capacitors:

• Value and type of capacitor: A 0.1 F (100 nF),

• Placement on the printed circuit board: The

• Handling high-frequency noise: If the board is

• Maximizing performance: On the board layout

2.2.2

On boards with power traces running longer than

six inches in length, it is suggested to use a tank capac-

itor for integrated circuits, including microcontrollers, to

supply a local power source. The value of the tank

capacitor should be determined based on the trace

resistance that connects the power supply source to

the device, and the maximum current drawn by the

device in the application. In other words, select the tank

capacitor so that it meets the acceptable voltage sag at

the device. Typical values range from 4.7 F to 47 F.

DS39933D-page 32

10-20V capacitor is recommended. The capacitor

should be a low-ESR device, with a resonance

frequency in the range of 200 MHz and higher.

Ceramic capacitors are recommended.

decoupling capacitors should be placed as close

to the pins as possible. It is recommended to

place the capacitors on the same side of the

board as the device. If space is constricted, the

capacitor can be placed on another layer on the

PCB using a via; however, ensure that the trace

length from the pin to the capacitor is no greater

than 0.25 inch (6 mm).

experiencing high-frequency noise (upward of

tens of MHz), add a second ceramic type capaci-

tor in parallel to the above described decoupling

capacitor. The value of the second capacitor can

be in the range of 0.01 F to 0.001 F. Place this

second capacitor next to each primary decoupling

capacitor. In high-speed circuit designs, consider

implementing a decade pair of capacitances as

close to the power and ground pins as possible

(e.g., 0.1 F in parallel with 0.001 F).

from the power supply circuit, run the power and

return traces to the decoupling capacitors first,

and then to the device pins. This ensures that the

decoupling capacitors are first in the power chain.

Equally important is to keep the trace length

between the capacitor and the power pins to a

minimum, thereby reducing PCB trace

inductance.

SS

, is required.

Power Supply Pins

DECOUPLING CAPACITORS

TANK CAPACITORS

DD

, V

SS

, AV

DD

and

2.3

The

functions: Device Reset, and Device Programming

and Debugging. If programming and debugging are

not required in the end application, a direct

connection to V

addition of other components, to help increase the

application’s resistance to spurious Resets from

voltage

configuration is shown in Figure 2-1. Other circuit

designs may be implemented, depending on the

application’s requirements.

During programming and debugging, the resistance

and capacitance that can be added to the pin must

be considered. Device programmers and debuggers

drive the MCLR pin. Consequently, specific voltage

levels (V

not be adversely affected. Therefore, specific values

of R1 and C1 will need to be adjusted based on the

application and PCB requirements. For example, it is

recommended that the capacitor, C1, be isolated

from the MCLR pin during programming and

debugging operations by using a jumper (Figure 2-2).

The

operations.

Any components associated with the MCLR pin

should be placed within 0.25 inch (6 mm) of the pin.

FIGURE 2-2:

Note 1: R1 10 k is recommended. A suggested

MCLR

jumper

2: R2 470 will limit any current flowing into

Master Clear (MCLR) Pin

IH

sags,

and V

V

starting value is 10 k. Ensure that the

MCLR pin V

MCLR from the external capacitor, C, in the

event of MCLR pin breakdown, due to

Electrostatic Discharge (ESD) or Electrical

Overstress (EOS). Ensure that the MCLR pin

V

IH

DD

R1

pin

JP

and V

is

C1

DD

IL

may

) and fast signal transitions must

replaced

may be all that is required. The

provides

IL

EXAMPLE OF MCLR PIN

CONNECTIONS

specifications are met.

IH

R2

2010 Microchip Technology Inc.

and V

be

MCLR

PIC18FXXJXX

IL

beneficial.

for

two

specifications are met.

normal

specific

A

run-time

device

typical

Related parts for MA180025

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet:

Part Number:

Description:

Manufacturer:

Microchip Technology Inc.

Datasheet: